Sprial Welding Finned Tube

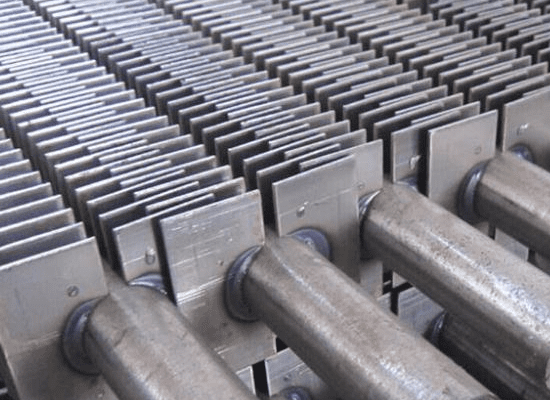

H Type Finned Tube

High-frequency welded spiral finned tube is one of the most widely used spiral finned tubes, and is now widely used in power, metallurgy, waste heat recovery in the cement industry and petrochemical industries. The high-frequency welded spiral finned tube is to use the skin effect and proximity effect of high-frequency current to heat the outer surface of the steel strip and the steel tube until the plastic state or melting, while the steel strip is wound around the steel tube, under a certain pressure of the winding steel strip. Finish welding. This high-frequency welding is actually a solid-phase welding. Compared with methods such as inlay, brazing (or integral hot-dip galvanizing), it is more advanced in terms of product quality (high welding rate of fins, up to 95%), productivity and automation.

Finned tubes are the main components of heat exchangers. They are a series of tubes where fins have been added on the outside to increase the contact area with the outside fluid, to exchange heat and between the fluid inside the tube and the fluid outside the tube. Finned tubes are elongated aluminium cladded carbon steel flat tubes with brazed aluminium fins.

Multiple types and shapes of finned tubes exist including round tubes, oval tubes, or flat tubes. Flat tubes, made of aluminium clad carbon steel tubes with aluminium brazed fins, are the state of the art for power plant air cooled condensers.

Address: Cangzhou City, Hebei Province, China

Contacts: Howie Li

Whatsapp Number: 0086 15530722107

Email: datangfintube@gmail.com

Looking forward to receiving your inquiry, I will offer you a very reasonable price.

Any questions, I will reply you within 24 hours.