Products

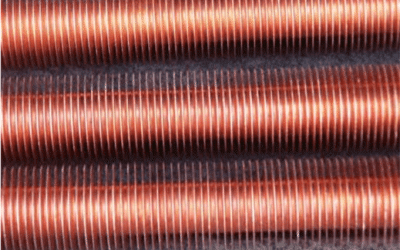

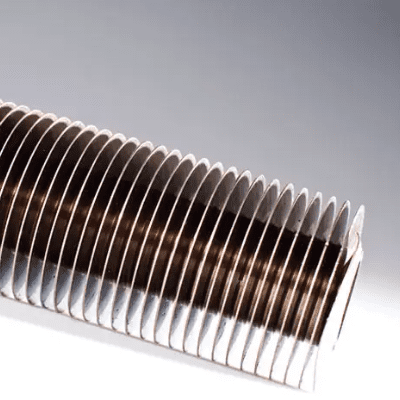

Optimized surfaces for a highly efficient heat transfer.With a great variety of materials we ensure to use the material best suited to the specific needs, for example concerning durability and formability.

About Us

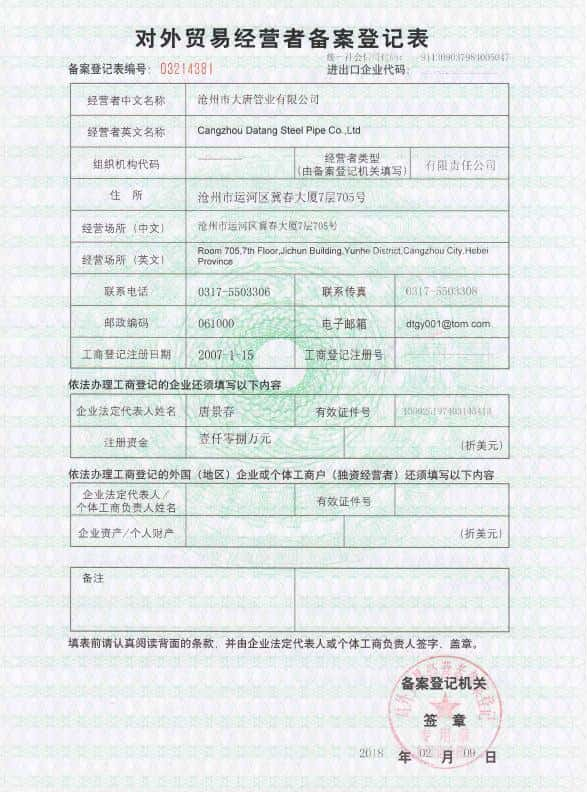

Cangzhou Datang Steel Pipe Co., Ltd has high frequency resistance welding finned tube production line 18, extruded finned tube equipment 30, laser welding finned tube production line 2, wound finned tube production line 12.

Why Choose Us

Finned Tube Application

We will do our utmost to meet your finned pipe/tube requirements. Plant turnarounds and other situations requiring high responsiveness are our specialty. We would welcome the opportunity to quote your heat transfer requirements.

Chemical

The finned tube is mainly used for the waste heat recovery and heating gas of the preheater soot to increase the exhaust air temperature of the heat treatment furnace. The catalytic device of chemical plant regenerates soot and waste heat recovery of various internal and external water heaters, which can generate high-pressure steam and use it for power plants.

Greenhouse

Finned tube radiators are often used in heating systems in large places. Finned tube radiators have been widely used in agriculture, industry, greenhouses and other fields.

Architecture

The engineering finned tube radiator is assembled by the high-frequency welded finned tube produced by our company. It is an important cooling device in the large-area indoor and large-area building heating system.

Electricity

Finned tube radiators have been widely used in the air cooling system of thermal power plants in power plants. Because the characteristics of the finned tube radiator can directly affect the heat exchange efficiency of the intercooling system. In general, finned tube radiators are basically designed according to a certain working condition in a steady state.

News

To understand the heat transfer principle of finned tubes, let’s first understand what the heat transfer coefficient is. The heat transfer coefficient refers to the amount of heat transfer per unit temperature difference and unit heat transfer area, which can reflect the heat transfer capacity between the fluid and the wall.

Cold-rolled (dial) carbon steel pipes are divided into general steel pipes, low- and medium-pressure boiler steel pipes, high-pressure boiler steel pipes, alloy steel pipes, stainless steel pipes, petroleum cracking pipes, and other steel pipes, as well as carbon thin-wall steel pipes, alloy thin-wall steel pipes, and stainless steel pipes. Rusty thin-walled steel pipes, special-shaped steel pipes.

The finned tube heat exchanger achieves the purpose of enhancing heat transfer coefficient by adding fins to the ordinary base fin tubes, and can have a heating effect. When heating is required, it can use high-temperature water, steam or high-temperature heat transfer oil to heat the air. When cooling is required, low-temperature water (such as chilled water) can be used to cool the air.