ASTM B280 Tp2 Seamless Copper Tube Inner Grooved Fin Tube for Refrigerator Condencer

Datang manufactures low fin tubes for heat exchangers used mainly in LNG facilities, chemical and petrochemical plants, refineries, power plants, renewable energy and naval systems.

Low fin tubes are obtained through a rolling process, which is a cold plastic deformation directly on the outer surface of the tube.

The low finning process greatly increases the surface area of heat exchange.

Materials

- Low-alloy steels

- Carbon steel

- Stainless steel (austenitic, ferritic, super austenitic)

- Duplex alloys (Lean Duplex, Duplex and Super Duplex)

- Monel alloys

- Nickel alloys

- Copper alloys

- Titanium

Production Capacity (approximate)

| Parameter | Metric Units | Imperial Units | Notes |

|---|---|---|---|

| Tube Diameter | 12.7 / 31.75 mm | 0.5 / 1.25 in | |

| Wall Thickness | 1.245 / 3.404 mm | 0.049 / 0.134 in | |

| Fin Height | Max. 1.40 mm | Max. 0.055 in | Depends on required fin pitch |

| Tube Length | Max. 22000 mm | Max. 866 in |

For different technical specifications, please feel free to contact us. Together we can find the most suitable solution.

Fin Pitch

| Copper | Ferritic | Austenitic | Titanium | Alloys | |

| Fins/inch | 16 to 40 | 19 to 30 | 19 to 36 | 19 to 36 | 16 to 40 |

| Fins/meter | 630 to 1574 | 748 to 1181 | 748 to 1417 | 748 to 1417 | 630 to 1574 |

Dimensional Tolerances

Our company meets the generally required standards for low fin tubes, namely:

- ASTM/ASME B/SB 111 (Copper & Copper Alloys)

- ASTM/ASME A/SA 498/498M (Carbon steel)

- ASTM/ASME A/SA 1012/1012M (Stainless steel)

- ASTM/ASME B/SB 891/891M (Titanium)

Quality Checks

We perform air tests at a range between 10 bar and 18 bar for 10 seconds and/or hydraulic pressure leak tests if requested by the customer.

We perform non-destructive tests (after finning).

Depending on the client’s needs, we are available to perform special tests and treatments.

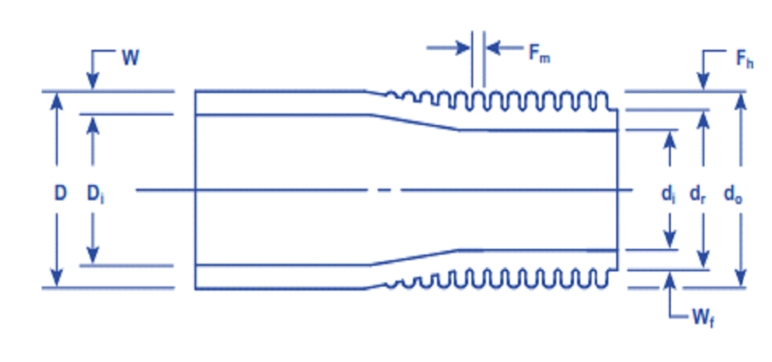

Dimensional Checks

We measure:

- outside diameter of plain end (D)

- inside diameter of plain end (Di)

- wall thickness of plain end (W)

- diameter over fins (do)

- root diameter (dr)

- inside diameter of fin section (di)

- wall thickness under fin (Wf)

- mean fin thickness (Fm)

- height of fin (Fh)

- fin pitch

We perform a complete visual check.

Packaging

We offer different packaging solutions in order to meet your needs:

- hexagonal and protected bundles

- nylon

- wooden crates and/or cages.

These methods will ensure a safe and organized transportation of your products.

Fin tube specifications:

| PRODUCT | DESCRIPTION | TUBE MATERIAL | FIN MATERIAL | TUBE SIZE | FIN SIZE |

|

High Finned Tube |

Extruded Fin tube

|

All Kind of Material can be applied | Aluminum A1050,

A6061 |

15.88~50.8 |

7~11.5FPI

Fin Height Max 16mmH |

| L-fin tube

(Wrap On Type) |

All Kind of Material can be applied |

Copper C1100,C1220 |

12.70~50.8 |

7~11.5FPI

Fin Height Max 16mmH |

|

| G-fin Tube (Imbeded Type)

|

Aluminum A1100,

A1050,A1060 |

||||

| High frequency Welded Finned

Tube H,HH

|

Carbon Steel Tube | Carbon Steel Tube |

12.7~160 |

1.5~7FPI

0.8~3.2mm. Thickness |

|

| Stainless Steel Tube | Stainless Steel Tube | ||||

| Alloy Steel Material | Alloy Steel Material | ||||

| Integral Copper&Copper Alloy

High Finned Tube |

C12200,C11000,C70600 | C12200,C11000,

C70600 |

15.88~22.23 | 5~9FPI

Max 12mm.H |

|

| Oval Finned Tube

STUD FIN TUBE |

Carbon Steel Tube | Carbon Steel Tube |

All SIZE Available |

5~15FPI |

|

| Stainless Steel Tube | Stainless Steel Tube | ||||

| Alloy Steel Material

Copper&Copper Alloy Tube |

Alloy Steel Material

Copper&Copper Alloy Tube |

||||

|

Monometallic Fin Tube |

Low Fin Tube | Carbon Steel,Stainless Steel,

Titanium,copper,brass,nickel Alloy,etc. |

— |

9.52~40 |

12,16,19,28 FPI,etc. |

| Turbo-C Tube | |||||

| Turbo-E Tube | |||||

| Corrugated Tube | All Kind of Material | — | 6.35~40 | 2~9FPI |