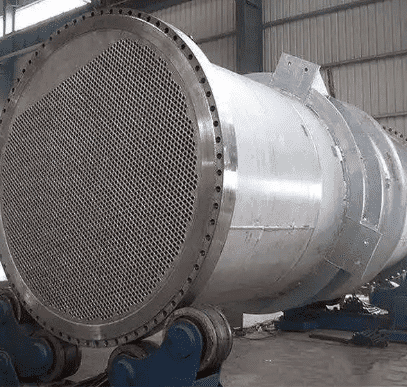

Tube bundle heat exchanger is a typical heat exchanging device that make two liquid with different temperatures to exchange heat.

Through the heat exchanger tank, one fluid can be cooled down and the other fluid can be heated to meet the required temperature.

Tube bundle collected many groups of pipe densly packed as a radiation core, outside installed with a tubular tank shell making from the pressure vessle steel plate, when hot liquid or gases are circulated in the tube bundle, the large combined surface area of the tubes will bring efficient heat exchanging performances to transfer heat into the tank shell water and cooling the fluids in the tubes.

Common use material for Tube Bundle Heat Exchanger

There are two different of tube bundles: Straight tubes and U tubes. Depending on specific requirement and application, there are following tube material options:

Carbon Steel Tube : ASTM A179/ASME SA179/179M, ASTM A192, ASTM A333, ASTM A334

Alloy Steel Tubes: ASTM A213 T5, T9, T11, T22, T91

Copper Tubes

Tank Shell Materia Options:

ASTM A516 GR70

ASTM A572 GR50

ASTM A537 CL1

Applications:

Chemical Production

Petroleum Industry

Energy Power

Pharmaceutical

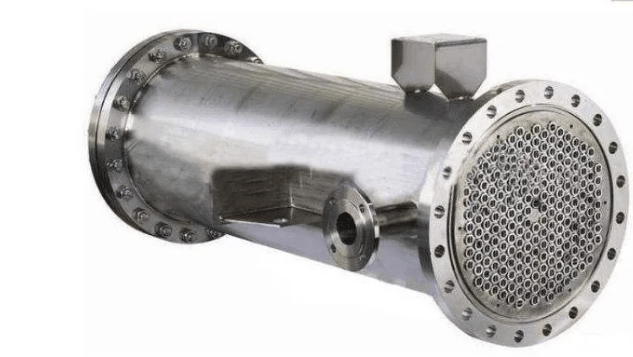

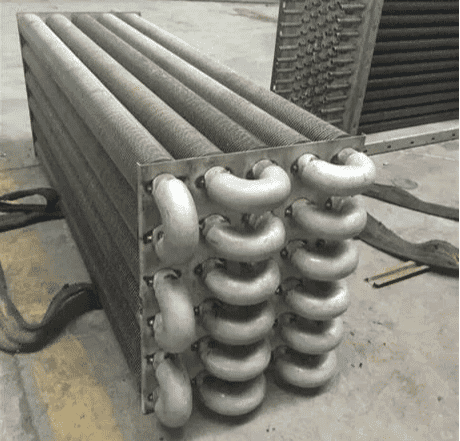

U Tube Bundle: The recommend and new common use tube bundle is the U tube layout. This bundle impressive features is entry and exit points on the same side of the shell on a tube shell cap divided into two sealed chambers.

The tubes manufactured in U shape, which it leaves the entry chamber and travel to the opposite end of the shell and return in the opposite direction to the exit chamber. This type of layout is easier to disassemble for maintenance with the bundle typically being slid out as a modular unit.

U type tube bundle also suited good with high temperature differences, relieve most thermal expansion and reduce contraction stresses in the bundle.