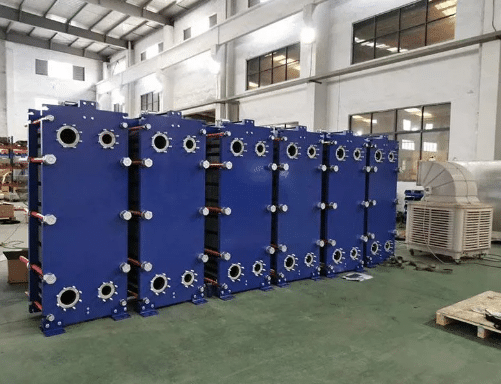

Plate Heat Exchanger Hydraulic Oil Cooler

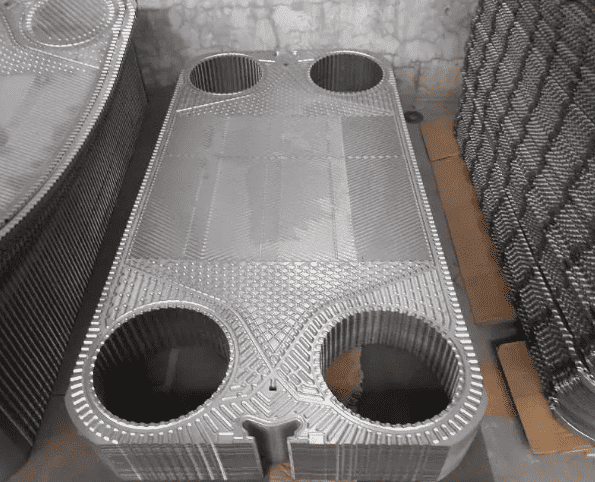

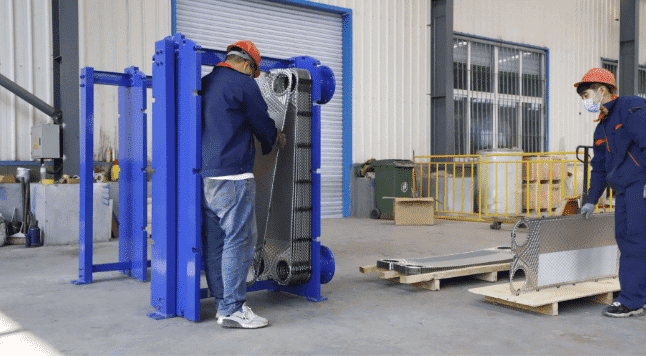

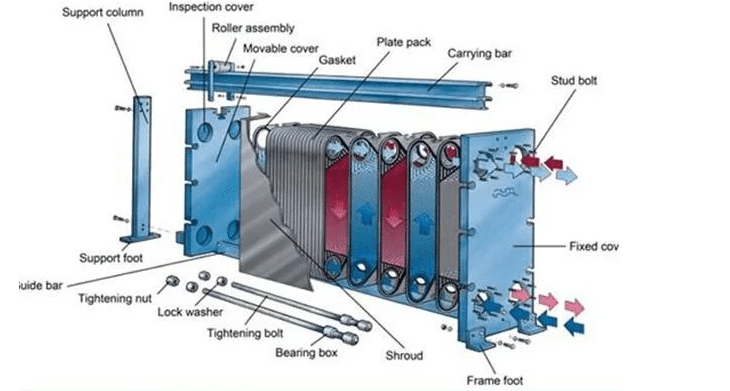

Plate heat exchanger is composed of heat transfer plates (corrugated metal plates) which are sealed by gaskets, tightened together by tie rods with locking nuts between frame plate. The port holes on the plate form a continuous flow path, the fluid runs into the path from inlet and is distributed into flow channel between heat transfer plates. The two fluids flows in counter current. Heat is transferred from hot side to cold side through heat transfer plates, the hot fluid is cooled down and the cold fluid is warmed up.

| Product Name | Best Factory Price Food Grade Stainless Steel Cross Flow Plate Heat Exchanger |

| Type | Plate Type |

| Plate Material | 304, 304L, 316, 316L, 254SMO, Duplex steel, Titanium, C-276 etc. |

| Nozzle dia. | DN32~DN1000mm |

| Plate pair pattern | Corrugated plate |

| Design pressure | Vacuum ~ 36 Bar |

| Plate thickness | 0.4~0.8 mm |

| Gasket materials | EPDM, NBR, VITON, PTFE CUSHION |

| Max. surface area | 4000m2 |

| Maximum design pressure | ≤10MPa |

| Maximum design temp | 850ºC |

| Maximum shell diameter | 4600mm |

| Tube specification | φ19-φ325mm |

| Tube length | 1000-16000mm |

In order to forward you a promt offer we would be pleased to receive you detailed enquiry including:

• Base tube material

• Base tube size (OD x WT x Length)

• Fin material

• Fin type

• Fin diameter or height

• Fin thickness

• Fins per inch, meter or fin pitch

• Lenght of plain, unfinned ends

• Finned Tube Quantity

(Additional fabrication, such as bend or weld the tubes into tubeplate or assembly)

• Base tube material

• Base tube size (OD x WT x Length)

• Fin material

• Fin type

• Fin diameter or height

• Fin thickness

• Fins per inch, meter or fin pitch

• Lenght of plain, unfinned ends

• Finned Tube Quantity

(Additional fabrication, such as bend or weld the tubes into tubeplate or assembly)