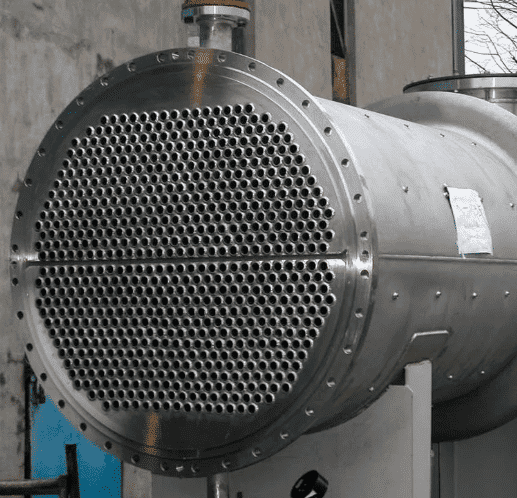

Tube bundle heat exchangers are primarily suited for heat transfer between various liquids and gases with or without phase change.

We offer fast production and quick shipping options:

- Complete heat exchanger production time is 3-6 weeks.

- Replacement Tube Bundles are 2-3 weeks.

Design and fabrication capabilities include:

- New and Replacement Units with ASME Section VII Division 1 requirements and TEMA B, C, and

R standards - 4” Nominal to 60” Nominal

- Shell and Tube type Units

- Industrial type exchangers for Chemical, Food Process and other industries.

- Aftercoolers, Oil Coolers, Suction Heaters, Tank heater and Fixed Tubesheet type Units.

- Standard design for complete exchangers is ASME Section VII Div. 1 TEMA C for 150 psig at

375°F. Other designs available upon request.

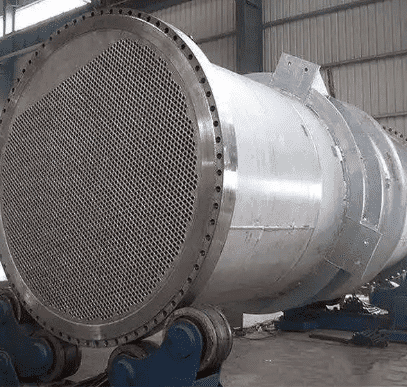

Double-Tube Sheet Heat Exchanger

Double-tube sheet design is adopted, with tube side and shell side connected with their own tube sheet, to minimize the risk of cross-contamination, to facilitate the timely detection of potential leakage, and to ensure the safety of production.

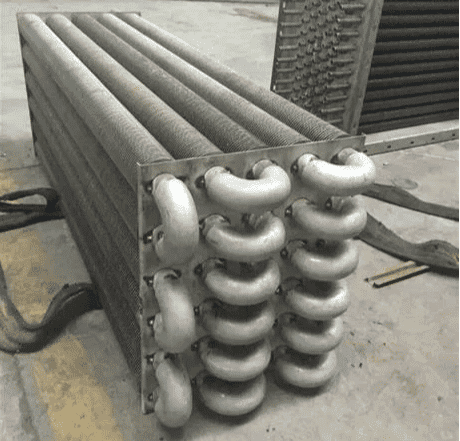

Double Tubes Heat Exchanger

Mainly used in the working conditions where the mixing of two media of the tube side and the shell side are strictly prohibited, such as chemical, metallurgy, food, polysilicon, etc. Double-tube sheet structure is adopted, completely avoiding the serious consequences of explosion, corrosion, etc. caused by the leakage of the shell-side and tube-side media.