Dry Air Cooler | Fin Tube Heat Exchanger

What is Dry Air Cooling?

Dry Air Coolers, variously known also as Air Blast Coolers or Fin Fan Coolers, are part of the ‘Dry Cooling’ technology family along with Air Cooled Condensers.

Air Blast Coolers cool liquid while Air Cooled Condensers cool steam.

The liquid to be cooled flows inside a network of tubes that have fins attached to facilitate heat transfer.

Ambient air is blown or drawn across the fins to cool the liquid inside.

Dry Air Coolers – Air Blast Coolers

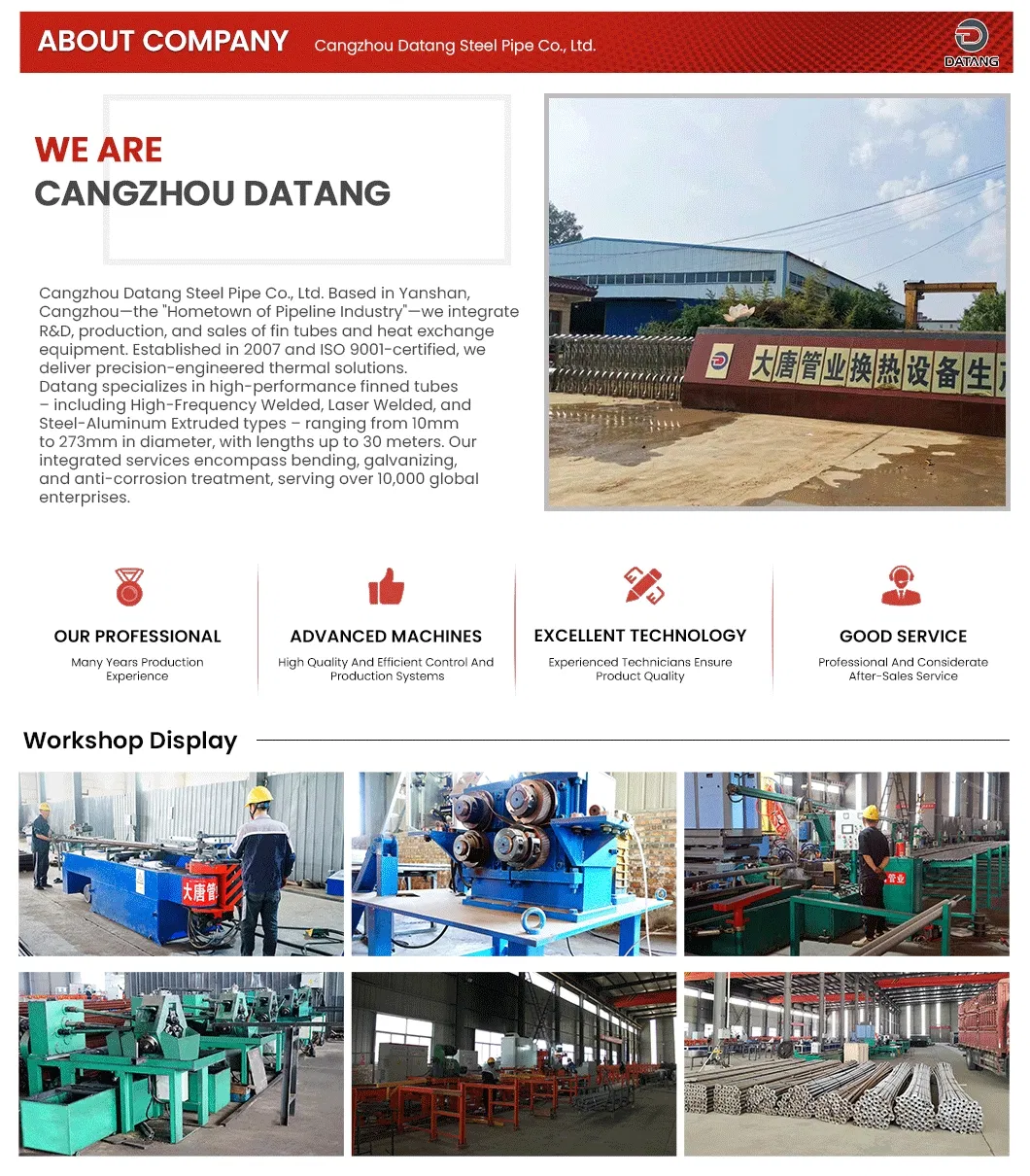

Datang Fin Tube provides industrial process cooling and HVAC related cooling solutions for the broadest range of applications including those with requiring ultra-precise sub-ambient air temperature fluid temperature control.

Horizontal Type Dry Air Cooled Heat Exchanger

Air cooled heat exchanger is a heat exchanger with fin tubes, and it can direct cool the medium by air without water.

And frced draft & induced draft are the most common ventilation types.

Dry Air Cooler Systems

A highly efficient heat exchange cooling system, dry coolers use convection and conduction to dissipate heat to the air using the fans mounted on top of the dry cooling unit, either using air or fluid in an adiabatic system. For the dry cooler system to work the temperature of the air needs to be cooler than the fluid in the system. They most commonly come in V and W bed configurations and are often seen in data centres where excess heat needs to be removed, but certain low humidity levels are not required.

After the initial installation a dry air cooler has a very low overall operating cost, due to both its durable and high-quality materials which make it resistant to types of corrosion and damage, as well as the lack of liquid evaporation which takes place, completely eliminating the need to make-up lost water. Sometimes referred to as free cooling, dry cooling systems are designed to be extremely effective and low-maintenance. Perfect for use as industrial air cooling.

Along with not requiring a constant water supply, the heat generated by dry fluid coolers can be channeled directly into other processes. This reduces wasted energy and improves the overall efficiency of the dry cooler system design

If you’re a smaller business, or just looking to maximise floor space, the convenient separation of components makes dry cooling systems a great compact cooling solution. At IPC we supply a range of dry coolers, adiabatic coolers and air-cooled condensers in a variety of specifications to meet the size requirements of as many businesses as we can, however if there isn’t one to suit you we also design bespoke dry cooling systems tailored to your requirements to ensure you receive the most effective dry air cooler system possible.

Dry cooled heat exchanger Applications

Dry cooled heat exchanger can be widely used in different industrial fields for heat transfer processes, such as: chemical, oil & gas, Oil Refining, power generation.

It is widely used in the desert oil industry air cooling system.

- Industrial liquid cooling e.g process water / water-glycol / thermal oil

- Remote radiator systems for generator sets

- Water-cooled compressor systems

- ORC cooling loops

- CHP engine/turbine heat dissipation

- Water-cooled chiller heat dissipation

- Compressed air system cooling

Dry Air Cooler | Fin Tube Heat Exchanger

Fan/ Low noise axial fans

Adopting a high-quality motor, the reasonable gap with the wind vane, guide ring, and hyperbolic designed ducting achieve maximum efficiency of the fan

Copper Pipe

Efficient use of multiple tooth inner thread pipe, Rate of more than 99.9%, increasing of the innertube surface area and improving the efficiency of heat transfer

The Pipeline Design

The heat exchanger is adopted directly back to the oil and counter exchanger area, improving the heat transfer efficiency and counter-current, to avoid the accumulation of oil and make full use of ensuring the superheat temperature of the heat exchanger.

Casing

Using3003 aluminum alloy shell or DC51-D+180g, spraying paint. For outdoor, and after high-temperature curing, the material has

high strength, and strong corrosion-resistance, standard color is RAL9010.

Dry coolers were designed to achieve an optimized exchange of thermal energy between air and a refrigerant or fluid. In order for dry cooler to work, the air temperature needs to be cooler than water in the system. To cool the system liquid, hot process liquid flows through the dry cooler tubes. The liquid is then cooled by the relatively cold ambient air that is forced through the coil.

The advantages are low maintenance cost, safe and reliable operation, long service life, and free of scaling.