Cast Iron Economizer for Boiler

Square Cast Iron Economizer:

150x250mm

200x300mm

300x500mm

A cast iron economizer is an auxiliary heating surface in a boiler system used to recover waste heat from the flue gas. By heating the feed water, the cast iron economizer improves the boiler’s overall thermal efficiency by 5%-10%.

What is a cast iron economizer?

A cast iron economizer is an auxiliary heating surface in a boiler system used to recover waste heat from the flue gas. By heating the feed water, the cast iron economizer improves the boiler’s overall thermal efficiency by 5%-10%. Made of cast iron, it is corrosion-resistant and wear-resistant, but has limited thermal stress tolerance. It is primarily used in boiler systems with operating pressures ≤ 2.5 MPa. During operation, thermal stress protection must be achieved by controlling the feed water temperature and flow rate. The design must match flue gas velocity and water velocity parameters to optimize heat transfer.

Structural Characteristics of Cast Iron Economizers

As the tail heating surface, cast iron economizers are technically different from steel tube economizers in terms of material. The fin structure is manufactured using a cast iron casting process. The number of damaged fins on a single tube must not exceed 5% of the total number of fins, and the overall number of damaged fins must be limited to 10%. Compared to steel tubes, cast iron economizers exhibit greater resistance to acid dew point corrosion in the low flue gas temperature range (typically below 400°C). However, due to the limited thermal conductivity of cast iron, heat transfer efficiency must be compensated by increasing the fin area.

Cast iron finned tubes are used to enhance heat transfer. Fins are added to the exterior of the tube to improve heat transfer efficiency. They are suitable for high-temperature, high-pressure, and corrosive environments. They are widely used in industrial boilers and power plant boilers.

Made of cast iron (gray cast iron or ductile iron), they offer stable thermal conductivity and strong corrosion resistance. They can withstand flue gas temperatures of 300-400°C and are not prone to deformation in high-temperature environments.

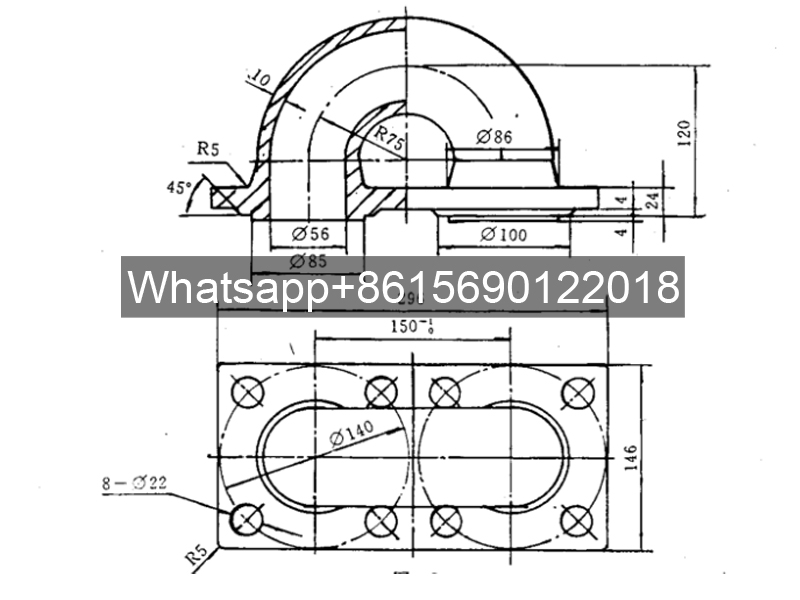

The cast iron elbow in a cast iron economizer is a key component used to connect economizer tube sections. It typically features a 180° elbow design to ensure heat transfer efficiency when flue gas flow changes direction.

The cast iron elbow connects the economizer tube sections into a single structure through a 180° bend, ensuring the continuity of the flue gas flow path and enhancing heat transfer through the elbow structure. This elbow is often made of cast iron, which offers high corrosion resistance and mechanical strength, and is suitable for low-pressure boiler systems (pressure ≤ 2.5 MPa).

Application Scope of Cast Iron Economizers

Application boundaries are defined based on boiler pressure parameters:

For operating pressures ≤2.5 MPa, cast iron is preferred.

For pressures exceeding 2.5 MPa or requiring a bubbling design, steel tube economizers should be used instead.

Cast iron economizers are commonly used with medium- and low-pressure equipment such as chain grate boilers, and they hold approximately 35% of the economizer market share in China’s industrial boiler sector.

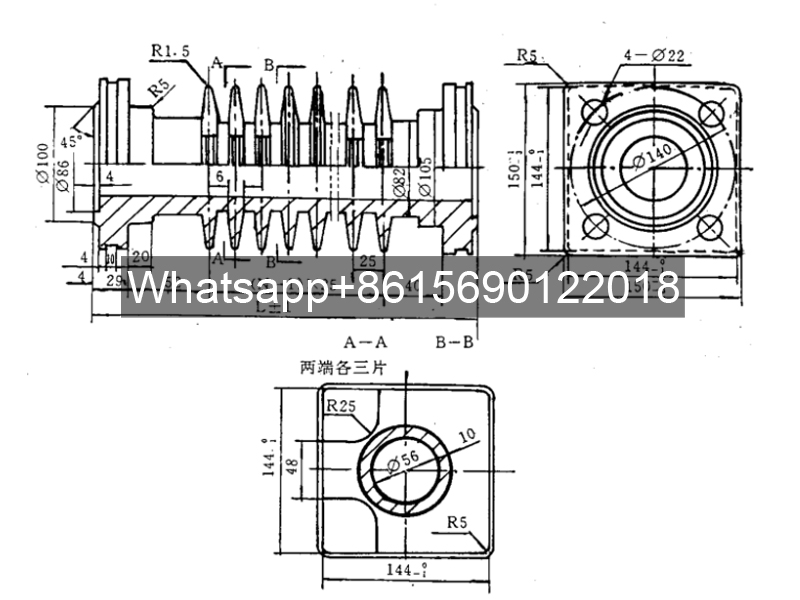

Square Cast Iron Economizer

I. Dimensions

Square cast iron economizers are typically available in various sizes, including 150*250mm, 200*300mm, and 300*500mm, suiting different heating applications.

II. Materials

Square cast iron economizers are primarily made of cast iron, which offers excellent high-temperature and corrosion resistance. Cast iron itself is also environmentally friendly and does not pollute the environment.

III. Thermal Efficiency

The thermal efficiency of a square cast iron economizer is a key indicator of its heating performance, primarily determined by its structure and material. Generally speaking, the higher the thermal efficiency of an economizer, the more fuel it saves and reduces environmental pollution. Currently, the thermal efficiency of square cast iron economizers on the market is generally above 80%.

IV. Applications

Square cast iron economizers are suitable for various heating applications, such as homes, hotels, factories, and schools. The heat energy generated by coal combustion can be used for heating or heating.

In short, square cast iron economizers are energy-saving and environmentally friendly heating equipment. Their dimensions, materials, and thermal efficiency all meet certain technical requirements. Selecting high-quality square cast iron economizers can effectively improve heating efficiency, save fuel, and reduce environmental pollution.

Cast Iron Economizer Operational Protection

Special protective measures are required during boiler startup:

The feedwater temperature should be controlled at no less than 20°C to avoid thermal shock, and the water velocity should be maintained at ≥0.5 m/s to prevent localized vaporization. Continuous feedwater circulation should be maintained during shutdown, and the bypass flue should be immediately opened in the event of an emergency shutdown.

Cast Iron Economizer Design Specifications

Cast iron economizer design must meet several technical requirements:

The flue gas velocity should be controlled between 8-12 m/s for optimal heat transfer, and the water velocity should be maintained between 0.3-0.5 m/s to balance resistance and heat transfer efficiency. Fin spacing should be designed to take into account the need for ash removal, with a minimum fin spacing typically ≥5 mm.