You Should Know About Longitudinal Finned Tubes

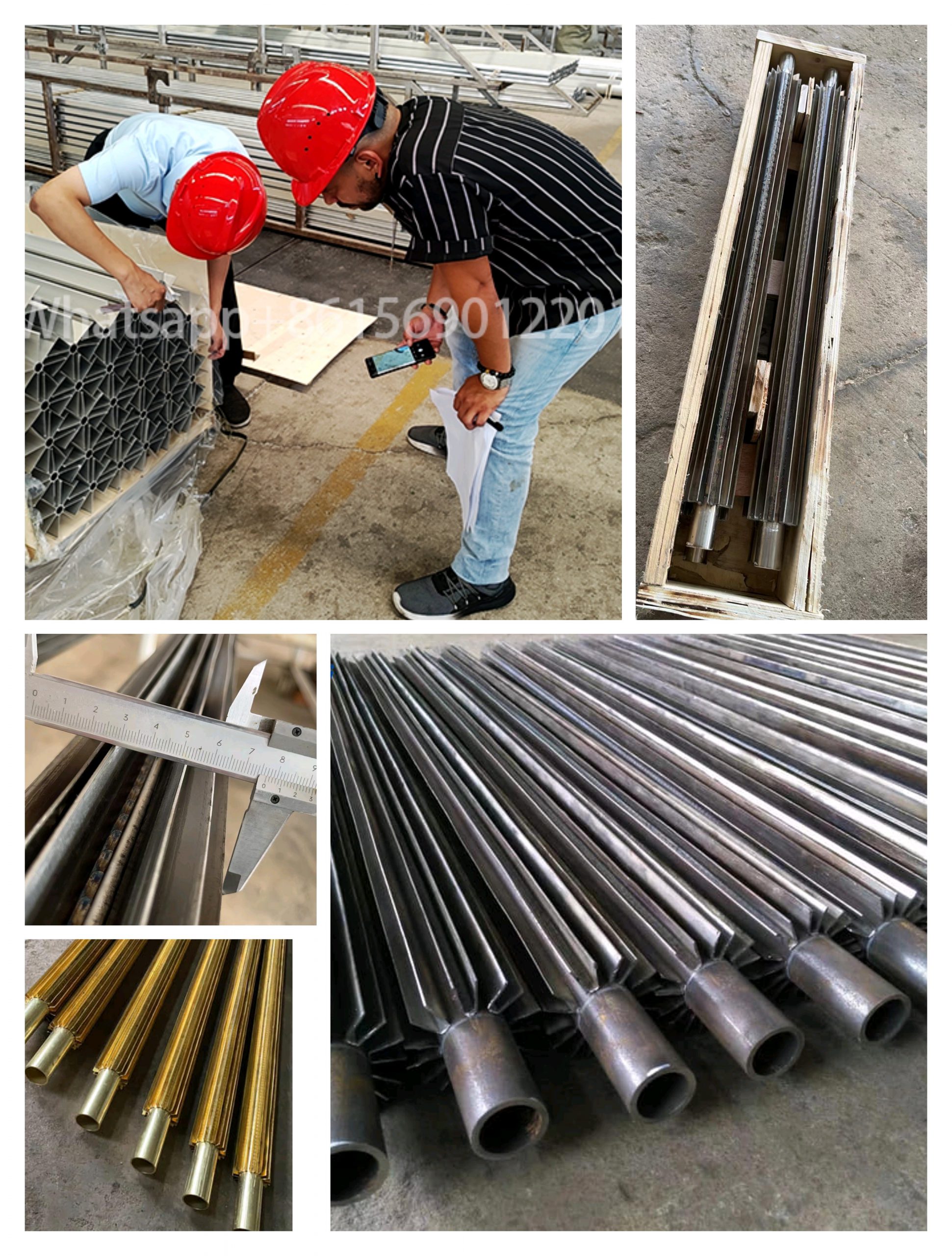

Longitudinal finned tubes are high-efficiency heat exchange elements. They increase the heat exchange area and improve heat transfer efficiency by welding longitudinal fins along the tube’s length.

The core feature of longitudinal finned tubes is their U-shaped stamped fin design, which offers advantages such as tight tube-fin fit, strong welding, low contact thermal resistance, and good straightness. The fin ratio can reach over 10.

Longitudinal Finned Tube Technical Parameters

Specifications: Tube diameter range 25-219mm; fin height and spacing can be customized.

Materials: Base tubes are commonly made of stainless steel or carbon steel; fins are mostly metals (such as aluminum or steel).

Longitudinal finned tubes, through optimized structural design, excel in enhancing heat transfer and saving space, making them a preferred solution in industrial heat exchange.

Longitudinal Finned Tube Structural Features

Fin Design: The longitudinal fins are combined with the base tube using resistance welding to form U-shaped channels, enhancing airflow turbulence and heat dissipation.

Material Selection: Base tubes are commonly made of stainless steel or carbon steel, while fins are mostly metal (such as aluminum or steel), balancing thermal conductivity and corrosion resistance.

Flexible Specifications: Wide range of tube diameters (e.g., 25-219mm), fin height and spacing can be adjusted according to requirements to suit different heat exchange scenarios.

Application Scenarios of Longitudinal Finned Tubes

Industrial Applications: Used in high-temperature and high-pressure environments such as petroleum, chemical, and boiler industries, as a core component of heat exchangers.

Civilian Equipment: Such as ovens and workshop hot air systems, utilizing their rapid heating and energy-saving characteristics.

Ground Source Heat Pumps: U-shaped longitudinal finned tubes offer superior heat exchange performance compared to bare tubes, especially when increasing flow velocity and reducing drilling depth.

Advantages and Performance of Longitudinal Finned Tubes

High-Efficiency Heat Transfer: Fins significantly increase the heat dissipation area, resulting in low air resistance, suitable for forced convection cooling. Durability: The seamless steel pipe substrate is reinforced, improving its pressure resistance, wear resistance, and corrosion resistance.

Economy: Mature processes such as high-frequency welding ensure controllable costs, making it suitable for large-scale production.