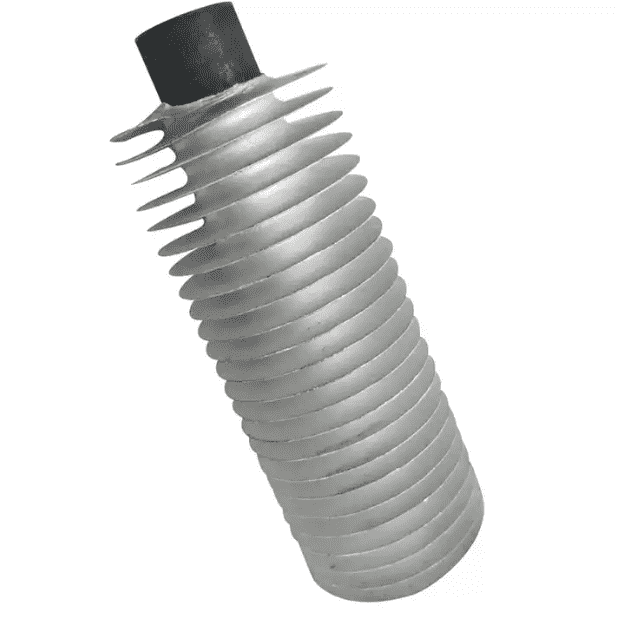

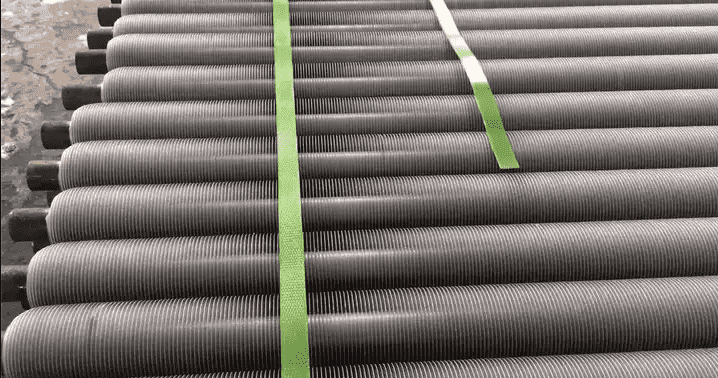

Aluminium Finned Tube

Inlaid finned tube

1)G-type finned tube(Embedded finned tube)

2)KL embossed wound finned tube

3)L wound finned tube

Contact Us:datangfintube@gmail.com

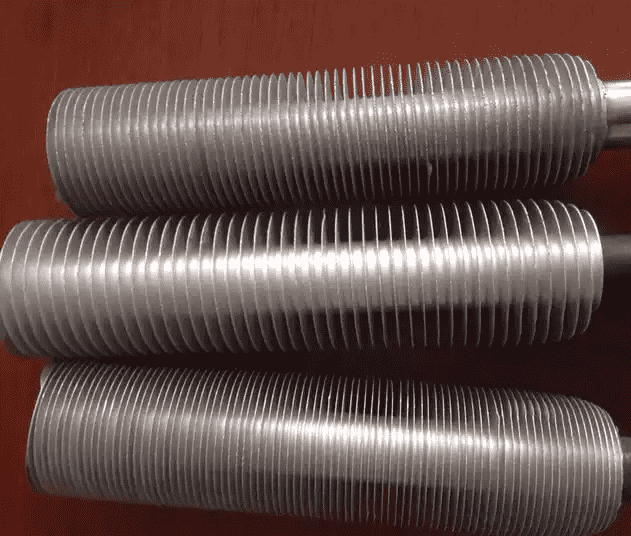

| Fin Material | Aluminium 1050/1060/1070/1100/5052/6063 |

| Fin Type | Solid or serrated or as per your drawing |

| Fin Pitch | Min. 1.5mm |

| Fins Per Pitch(Density) | 4-12 |

| Fin Segments | 12, 16, 24 fins or as per your design |

| Fin Height | Max. 16.5mm |

| Fin Thickness | 0.4mm Average |

| Core Tube Material | Aluminum alloy (Core tube with extremely thin wall materials can be applied.) |

| Base Tube OD | Max 2”(50.8mm) |

| Tube Wall Thickness | No Limit |

| Tube length | No limit |

| Accessories | Tube Support Box, Clamp & Spacer Box |

| Packaging Details | (1) Steel frame case sealed by plywoods with each end-capped. (2) Solid fumigated wooden box with each end-capped. |

All dimensions of aluminum finned tube in inches and specifications upon your request.

Tube OD | Fin Height | Fin Thickness | Fins per Pitch(Density) |

| 5/8 | 3/8, 1/2 | .015/.016/.020 | 4, 5, 6, 7, 8, 9, 10, 11, 12 |

| 3/4 | 3/8, 1/2, 5/8 | .015/.016/.020 | 4, 5, 6, 7, 8, 9, 10, 11, 12 |

| 1 | 3/8, 1/2, 5/8 | .015/.016/.020 | 4, 5, 6, 7, 8, 9, 10, 11 |

| 1 1/4 | 3/8, 1/2, 5/8 | .015/.016/.020 | 4, 5, 6, 7, 8, 9, 10, |

| 1 1/2 | 3/8, 1/2, 5/8 | .015/.016/.020 | 4, 5, 6, 7, 8, 9, 10, 11 |

| 1 3/4 | 3/8, 1/2, 5/8 | .015/.016/.020 | 4, 5, 6, 7, 8, 9, 10 |

| 2 | 3/8, 1/2, 5/8 | .015/.016/.020 | 4, 5, 6, 7, 8, 9, 10 |

The Finned Tubes are essentially Tubes with increased surface area. The amount of heat transferred from a particular surface is directly correlated to the surface area available for the heat to transfer. Hence, increasing the heat transfer area as a whole increases the heat transfer efficiency.

In a Finned Tube the Surface Area of the Tubes is increased by providing Fins on the Heat Exchanger. These fins can be of various types, made of various materials and designed in various ways depending on the end requirement.

Features:

Excellent resistance to corrosion

High fin stability

Withstand high temperature