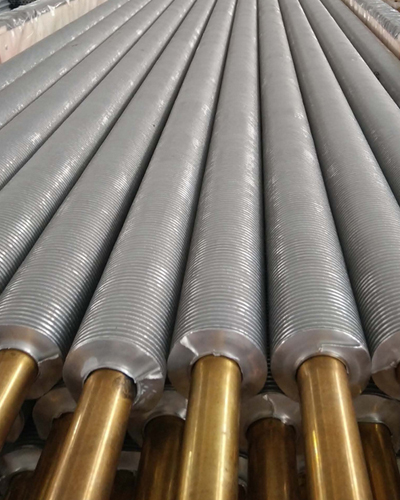

Aluminum Fins for Copper Pipe Extruded Finned Tube

The aluminum fins for copper pipe extruded finned tube is manufactured by compressing an aluminum bloom, or sleeve, onto the parent tube. The bloom is exposed to extremely high pressures which essentially “grows” the fins into the final fin profile. The process produces an extremely strong joint with excellent heat transfer capabilities.

Aluminum Fins for Copper Pipe Extruded Finned Tube Fabrication Process

For composite finned tube, we need to pipe line——compressing or rolling——strip peeling——washing——pressure test——blast blowing——packaging.

Finned tube is composited with iron-aluminum or copper-aluminum tube rolling out the fin, which feathers are tightness, small heat resistance, good heat transfer performance, high strength, small flow losses, strong corrosion resistant performance, not easy to deformation and a long working lifetime in cold and hot condition, etc.

Overall rolling fin is smooth and has no burr, so it is easy to clean. It is easy to make the fin surface wet and cooled with water when makes it cold during heating air-conditioning engineering. In the situation with drying, heating and other heat exchanging, its surface is handles by anodizing, which with beautiful color and luster, and can effectively prevent surface corrosion.

Aluminum rolling finned tube is rolling as a whole by the aluminum tube, which has the feather that no contact thermal resistance, high strength, thermal shock and mechanical shock, good thermal performance, and considerable expansion heat transfer surface. The heat exchanger with this kind of finned tube is ahead of the string or around the plate ones.

EXTRUDED FINNED TUBE SPECIFICATIONS

Bare Tube Materials: Copper, Alloy, Carbon Steel, Stainless Steel

Bare Tube OD:8-51mm

Fin Materials: Copper,Aluminum

Fin Pitch: 1.6-10mm

Fin Height:<17mm

Fin Thickness:0.2-0.4mm

Maximum Working Temperature:230℃

Materials StandardExtruded Bimetallic Finned Tube is combined with two different materials.

Base Tube

Carbon steel tube: SA179, SA334, SA214, SA106B, GB8163, GB9948, GB3087,10#, 20#,

Stainless steel tube: SA789, SA213, SA312, SA210, SA249, 304, 316L, T11, T22, T91

Copper tube: C1100, C12200, C44300, C68700, C70600, C71500, CuNi90/10, 70/10,70/20,70/30

Fin material: Aluminum 1060, 1050, 1070, 6063,6061,3003

The core component of copper tubes with aluminum fins is the copper tubing. Copper is highly regarded for its excellent thermal conductivity, making it an ideal material for efficient heat transfer. The copper tubing forms the inner layer of the assembly, ensuring quick and efficient heat transportation through conduction. Copper’s superior thermal conductivity allows for faster heat dissipation and uniform temperature distribution, enhancing overall system performance.

Aluminum Fins for Copper Pipe Applications:

Typically extruded fins are used in corrosive atmospheric conditions, such as off-shore applications, widely applied in equipment like water cooler, air cooler, heat exchanger, boiler and burners and so on.

Maximum working temperature is 285°C.

Refrigeration Copper Tube Aluminium Fin Condenser Coil

Highest quality product

Wider range of products in both geometry and materials

Price saving

Refrigeration Copper Tube Aluminium Fin Condenser Coil Highest Quality Product

The perfect bond between fin and tube improves efficiency in heat transfer and resistance to corrosion resulting in a clean weld fin to tube joint and fully straight fins (no corrugation).

Aluminum Fins for Copper Pipe Features High Production Efficlency

Utilizing a winding process, our aluminum fin tubes are produced with high efficiency, ensuring quick turnaround times without compromising quality.

Unlform Fin Pltch and Superior Heat Transfer

The uniform fin pitch ensures consistent heat transfer performance, maximizing the efficiency of your heat exchanger systems.

Protection Agalnst Corrosion

The core tube is protected from air corrosion by the base of the fin, ensuring long-term durability and reliability. Robust Construction

Our copper fin tubes are designed to withstand mechanical stress and atmospheric corrosion, making them suitable for a wide range of industrial applications.

Aluminum Fins for Copper Pipe Appl Reatlons

1. Air cooler in petrochemical, power plant, paper-making, tobacco and building heating.

2. Air heater in food processing equipment

3. Air heater in plant protein and starch spay drying system

Datang Servces

At Datang Fin Tube, we go beyond just providing products; we offer a comprehensive service package designed to meet and exceed your expectations:

Custom Solutlons: We tailor our products to meet the specific requirements of each client, ensuring a perfect fit for your unique needs.

Quallty Assurance: With an ISO 9001 certification, we guarantee the highest quality standards for our extruded fin tubes. Customer Satlsfaction: Our commitment to customer satisfaction is unwavering, ensuring you receive the best service and products.

Comprehenslve Range: From copper tubes to super duplex plpe fittings, we offer a wide selection to cater to all your needs.

Datang Fin Tube Technical Parameters

| PRODUCT | TYPE | TUBE MATERIAL | FIN MATERIAL | TUBE SIZE | FIN SIZE |

| Heat Exchanger Finned Tube | Extruded Fin Tube | All Kind of Material can be applied | Aluminum A1100 | 15.88~50.8 | 7~11.5FPI |

| Fin Height Max 16mmH | |||||

| L-Foot Fin Tube | All Kind of Material can be applied | Copper C1100, C1220 | 12.70~50.8 | 7~11.5FPI | |

| (Wrap On Type) | Fin Height Max 16mmH | ||||

| G-Fin Tube (Embedded Type) | Aluminum A1100, A1050, A1060 | ||||

| High Frequency Welded Finned Tube | A179 Carbon Steel Tube | Carbon Steel Tube | 12.70~160 | 1.5~7FPI | |

| Stainless Steel Tube | Stainless Steel Tube | 0.8~3.2mm. Thickness | |||

| Alloy Steel Material | Alloy Steel Material | ||||

| Integral Copper & Copper Alloy High Finned Tube | C12200, C11000, C70600 | C12200, C11000, C70600 | 15.88~22.23 | 5~9FPI | |

| Max 12mm. H | |||||

| Oval Finned Tube | Carbon Steel Tube | Carbon Steel Tube | All Size Available | 5~15FPI | |

| Stainless Steel Tube | Stainless Steel Tube | ||||

| Alloy Steel Material | Alloy Steel Material | ||||

| Copper & Copper Alloy Tube | Copper & Copper Alloy Tube | ||||

| Monometallic Fin Tube | Low Fin Tube | Carbon Steel, stainless steel, titanium, copper, brass, nickel alloy, etc. | — | 9.52~40 | 12, 16, 19 28 FPI, etc. |

| Turbo-C Tube | |||||

| Turbo-E Tube | |||||

| Corrugated Tube | All Kind of Material | — | 6.35~40 | 2~9FPI |