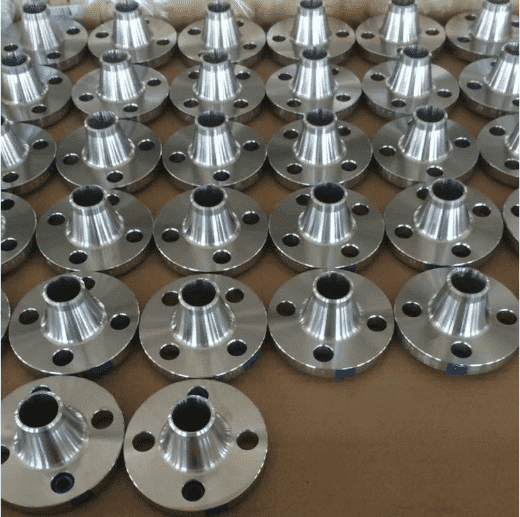

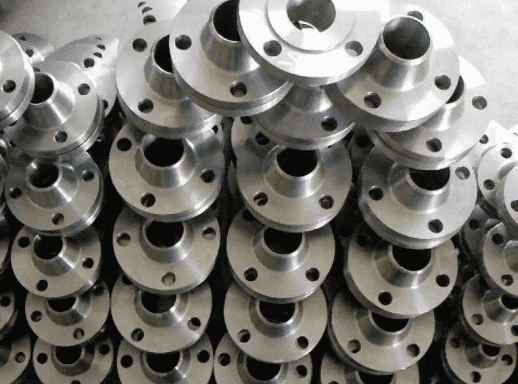

ASTM A182 Welding Neck Flange

Forged Flange

Standard:

ANSI B16.5, ANSI B16.47 SERIES A & B, DIN2573, 2572, 2631, 2576, 2632, 2633, 2543, 2634, 2545

Contact Us:datangfintube@gmail.com

Material:

Carbon Steel:ASTM A 105/A105N

Stainless Steel:ASTM A182 F304/304L, F316/316L, F321

Alloy Steel:ASTM A182 F1, F5, F9, F11, F12, F22, F91

| Size & Rating: 1/2″-48″ ANSI CL150-CL2500, DIN 6BAR-40BAR, JIS 5K-30K Face Type: Flat Face, Raised Face, Ring Joint Face, Lap Joint Face, Male Face, Female Face, Tongue & Groove Face Type: Welding Neck Flange, Slip On Flange, Blind Flange, Socket Welding Flange, Threaded Flange, Reducing Flange, Spectacle Blind Flange, Orifice Flange |

| ASTM A53 /A106 Chemical Components and Machanical Property | |||||||||||||

| Standard | Steel Grade | Chemical Components | |||||||||||

| C | Mn | P | S | Cu | Ni | Cr | Mo | V | |||||

| ASTM A53 | A | ≤0.25 | ≤0.95 | ≤0.05 | ≤0.045 | ≤0.40 | ≤0.40 | ≤0.40 | ≤0.15 | ≤0.08 | |||

| B | ≤0.30 | ≤1.20 | ≤0.05 | ≤0.045 | ≤0.40 | ≤0.40 | ≤0.40 | ≤0.15 | ≤0.08 | ||||

| Standard | Steel Grade | Chemical Components | |||||||||||

| C | Si | Mn | P | S | Cu ,Ni | Cr | Mo | V | |||||

| ASTM A106 | B | ≤0.30 | ≥0.10 | 0.29-1.06 | ≤0.035 | ≤0.035 | ≤0.40 | ≤0.40 | ≤0.15 | ≤0.08 | |||

| C | ≤0.35 | ≥0.10 | 0.29-1.06 | ≤0.035 | ≤0.035 | ≤0.40 | ≤0.40 | ≤0.15 | ≤0.08 | ||||

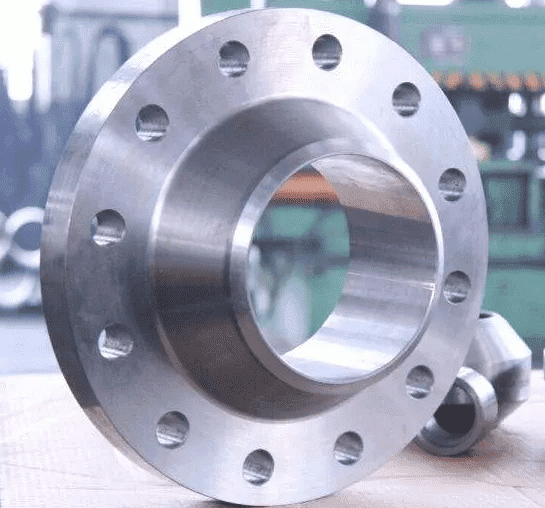

Welding Neck Flanges are easy to recognize at the long tapered hub, that goes gradually over to the wall thickness from a pipe or fitting.

The long tapered hub provides an important reinforcement for use in several applications involving high pressure, sub-zero and / or elevated temperatures. The smooth transition from flange thickness to pipe or fitting wall thickness effected by the taper is extremely beneficial, under conditions of repeated bending, caused by line expansion or other variable forces.

These flanges are bored to match the inside diameter of the mating pipe or fitting so there will be no restriction of product flow. This prevents turbulence at the joint and reduces erosion. They also provide excellent stress distribution through the tapered hub and are easily radiographed for flaw detection.

This flange type will be welded to a pipe or fitting with a single full penetration, V weld (Buttweld).