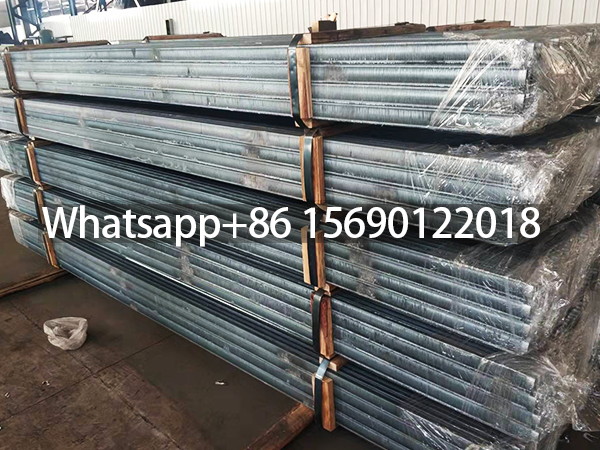

Features of Oval Finned Tubes(Elliptical Finned Tube)

Oval finned tubes are high-efficiency heat exchanger elements with a unique structure and working principle. Their characteristics and principles will be detailed below.

Working Principle of Oval Finned Tubes:

The working principle of elliptical finned tubes is based on the fundamental principles of heat conduction and convection heat transfer.

Optimized Fin Structure of Oval Finned Tubes:

The fin structure of elliptical finned tubes is designed in an elliptical shape. This shape allows for a larger surface area within the same volume. When the medium passes through the finned tube, effective heat exchange occurs between the fin surface and the medium. The elliptical fin design increases the contact area between the fins and the fluid, improving heat exchange efficiency.

Enhanced Heat Exchange Efficiency of Oval Finned Tubes:

One of the main features of elliptical finned tubes is their unique fin structure. The elliptical fins significantly increase the contact area with the fluid compared to traditional rectangular fins, thereby improving heat exchange efficiency. This design allows elliptical finned tubes of the same size to achieve higher heat exchange performance.

Elliptical finned tubes offer strong adaptability:

Elliptical finned tubes are suitable for various industrial and commercial applications, handling diverse media and operating conditions, including high temperature, high pressure, and corrosive media. Their design ensures excellent performance and reliability in diverse environments.

Elliptical finned tubes save space:

Compared to other types of finned tubes, elliptical finned tubes, due to their superior heat exchange efficiency, can reduce the overall size and weight of the heat exchanger while maintaining the same heat exchange capacity, saving installation space and costs.

Elliptical finned tubes reduce pressure drop:

The design of elliptical finned tubes not only increases the heat exchange surface area but also effectively reduces the flow resistance and pressure drop of the medium within the tube, improving system energy efficiency. This is particularly important for industrial applications requiring reduced energy consumption.

Elliptical finned tubes offer strong corrosion resistance:

Finned tubes are typically made of high-strength, corrosion-resistant materials such as stainless steel and aluminum alloys, resisting the erosion of various chemical media and environments, extending the service life of the finned tubes, and reducing maintenance costs.

Stable Operation of Elliptical Finned Tubes:

Elliptical finned tubes are designed and manufactured with high precision, and the assembly process is strictly controlled, ensuring their stability and reliability during long-term operation and reducing downtime and failures.

Heat Conduction and Convective Heat Transfer in Elliptical Finned Tubes:

Heat conduction refers to the transfer of heat through the fin material to the fin surface, and then to the medium through convection. When the medium flows inside the tube, it comes into contact with the fin surface. The elliptical shape of the fins allows the medium to flow effectively along the fin surface, increasing the efficiency of heat transfer between the medium and the fin.

Optimized Fluid Dynamics in Elliptical Finned Tubes:

Elliptical finned tubes improve the dynamic characteristics of fluid flow within the tube by optimizing the fin shape and spacing. This optimization helps reduce flow resistance and pressure drop, improving the overall system energy efficiency and reducing operating costs.

Elliptical finned tubes adapt to diverse operating conditions:

The design of elliptical finned tubes takes into account adaptability under various operating conditions, enabling them to withstand complex environments such as high temperature, high pressure, and corrosive media. This design has led to the widespread application of elliptical finned tubes in industries such as chemical, power, and pharmaceutical, providing reliable heat exchange solutions for industrial production.

Due to their excellent heat exchange efficiency, space-saving design, strong adaptability, and good corrosion resistance, as well as their working principle based on heat conduction and convection heat transfer, elliptical finned tubes have become important heat exchanger components in modern industry, widely used in various industrial production and manufacturing processes.