Plate Heat Exchanger Design

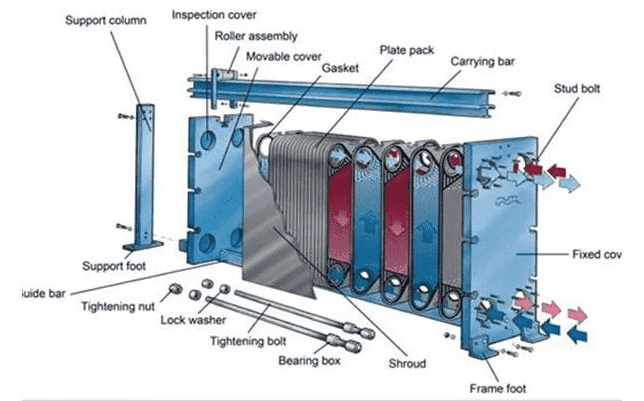

Easy disassembly for inspection or maintenance

Able to withstand temperature approaches of less than 1°C

“U” or “K “ values three to six times higher than shell and tube exchangers

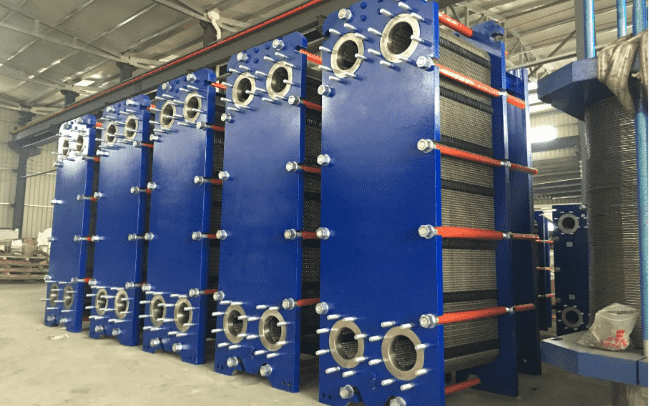

he plate heat exchanger is a type of heat exchanger that can be installed in the process line or utility line to heat or cool a fluid.

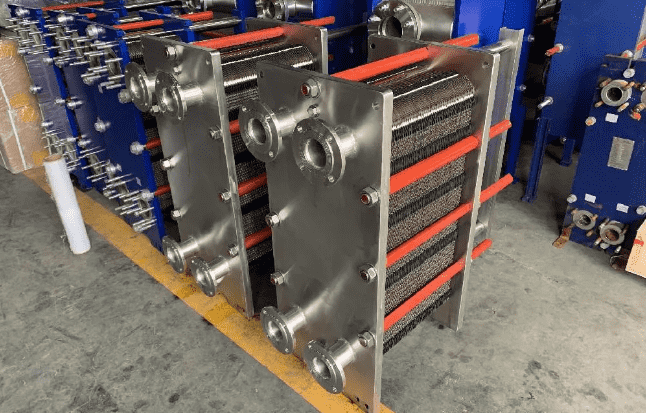

It uses a very thin sheet of corrosion-resistant metal (such as stainless steel, or titanium) to transfer heat between two fluids. Compared to a conventional heat exchanger, a plate heat exchanger has a larger surface area, thus the heat transfer rate is increased.

EFFICIENT

High heat transfer coefficiency — corrugated stainless steel plate and counter flow style

Maximum heat transfer coefficient: 7000W/m2K

CUSTOM-MADE

Wide selection of materials — plates(SS304, SS316L, SMO254,Ti,Ni,Hastelloy), gaskets(NBR, EPDM, HNBR, Fluororubber/Viton, Silicon)

Multi-media available — water to water(fluid to fluid), steam to water(gas to fluid)

According to various applications, we will design the optimal product for your requirements

CONVENIENT

Easy cleaning — smooth surface, detachable plates

Small floor area — compact size

RELIABLE

15-year experience in heat exchanger and pressure vessel

Strong technical team — 5 senior engineers (over 20 years experience)

Quality guaranteed — CE,SGS,ISO9001 certified, 18 patents

Warranty — 1 year guarantee