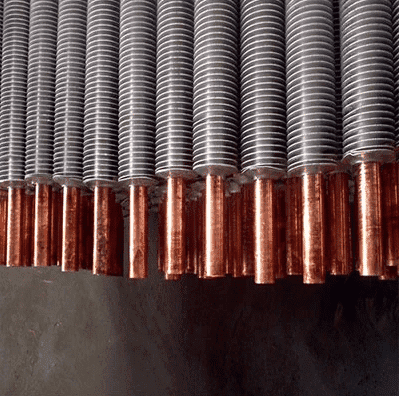

Copper Tube Composited Extruded Fin Tube with Aluminum Fin

The extruded fin is manufactured by compressing an aluminum bloom, or sleeve, onto the parent tube. The bloom is exposed to extremely high pressures which essentially “grows” the fins into the final fin profile. The process produces an extremely strong joint with excellent heat transfer capabilities.

Fabrication Process

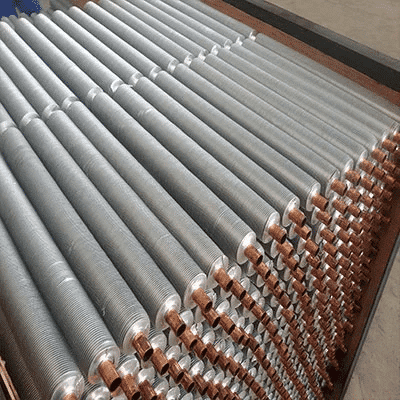

For composite finned tube, we need to pipe line–compressing or rolling–strip peeling–washing–pressure test–blast blowing–packaging.

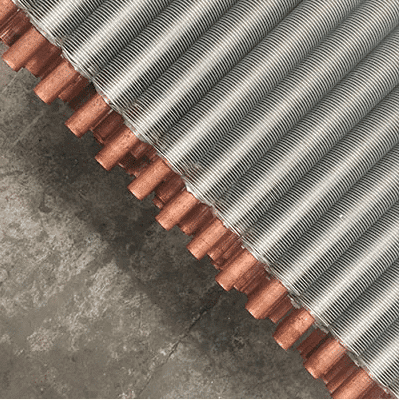

Finned tube is composited with iron-aluminum or copper-aluminum tube rolling out the fin, which feathers are tightness, small heat resistance, good heat transfer performance, high strength, small flow losses, strong corrosion resistant performance, not easy to deformation and a long working lifetime in cold and hot condition, etc.

Overall rolling fin is smooth and has no burr, so it is easy to clean. It is easy to make the fin surface wet and cooled with water when makes it cold during heating air-conditioning engineering. In the situation with drying, heating and other heat exchanging, its surface is handles by anodizing, which with beautiful color and luster, and can effectively prevent surface corrosion.

Aluminum rolling finned tube is rolling as a whole by the aluminum tube, which has the feather that no contact thermal resistance, high strength, thermal shock and mechanical shock, good thermal performance, and considerable expansion heat transfer surface. The heat exchanger with this kind of finned tube is ahead of the string or around the plate ones.

EXTRUDED FINNED TUBE SPECIFICATIONS

| Tube Material | Stainless Steel, Copper, Carbon steel, Alloy |

| Tube OD | 10-57mm |

| Tube Wall Thickness | 1.0mm-4.0mm |

| Fin Material | Aluminum, copper |

| Fin OD | 25~82mm |

| Fin thickness | 0.2~1mm |

| Fin Pitch | 1.8~8mm |

| Fin Height | less than 18mm |

Extruded Bimetallic Finned Tube is combined with two different materials.Materials Standard

Base Tube

Carbon steel tube: SA179, SA334, SA214, SA106B, GB8163, GB9948, GB3087,10#, 20#,

Stainless steel tube: SA789, SA213, SA312, SA210, SA249, 304, 316L, T11, T22, T91

Copper tube: C1100, C12200, C44300, C68700, C70600, C71500, CuNi90/10, 70/10,70/20,70/30

Fin material: Aluminum 1060, 1050, 1070, 6063,6061,3003

Applications:

Typically extruded fins are used in corrosive atmospheric conditions, such as off-shore applications, widely applied in equipment like water cooler, air cooler, heat exchanger, boiler and burners and so on.

Maximum working temperature is 285°C.