The following table shows common Aluminum Embedded Finned Tube configurations:

Tube OD: 1”, 1-1/4” and 1-1/2″

Tube Wall: .083″ minimum

Fin Height: 1/2” and to 5/8″

Fin Type: Solid

Fin Thickness: 0.016″

Number of fins: 8 to 11 fin per inch

Fin Material: Aluminum 1100-0

Tube Material: Generally carbon steel or stainless steel

Tube Length: No practical limit

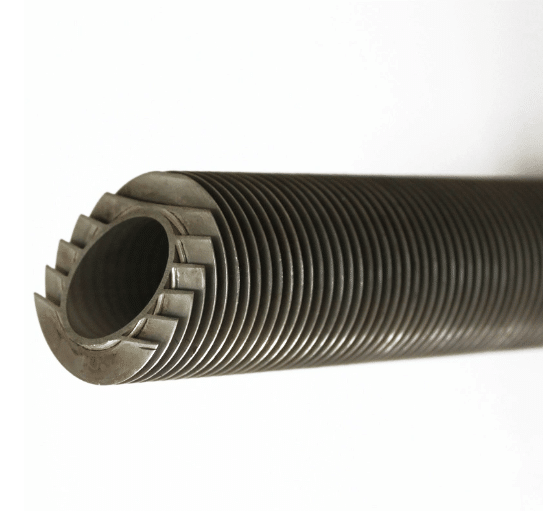

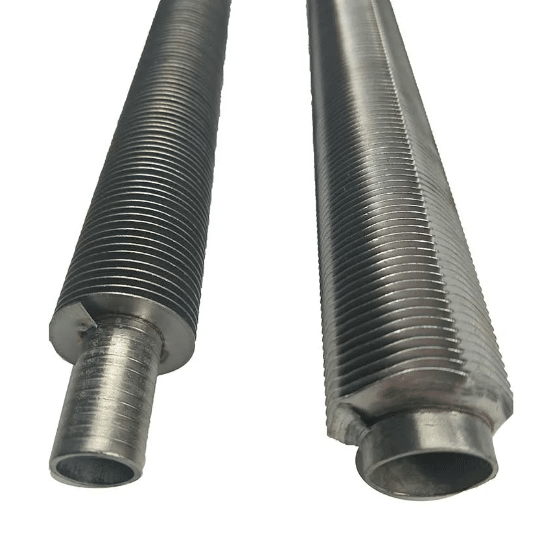

Embedded Finned Tube

Energy Transfer embedded finned tubing offers exceptional thermal efficiency at higher temperature ranges with solid fin-to-tube contact. Fins are mechanically locked into a helical groove in the outside of the tube. Rollers press displaced metal from the groove against the base of the fin to form a lasting metal-to-metal bond.

Including G Embedded Fin Tubes, Knurled L Fin Tubes, L Wrap-on Fin Tubes, Double L Finned Tubes, Bimetal Finned Tubes

Fin Tubes are indispensable design elements where heats are to be transferred economically between gases and liquids or between gases and condensing vapors, for that reason, finned tube heat exchangers are preferably used to cool or heat gases, especially air.

Titanium Finned Tubes, Stainless Steel Finned Tubes, Aluminum Fin Tubes, Copper Finned Tubes, Copper / Nickel Finned Tubes, Carbon Steel Finned Tubes.

Application:

Fin tubes are widely used in Sinopec, PetroChina, CNOOC, electric power, metallurgy and other industries. Due to the high quality of our products, fast and punctual delivery, reasonable price and good after-sales service, our company has acquired the recognition of the industry and the trust of our clients.

The common application fields are:

Heat exchangers units for power plant (electric, nuclear, thermal and geothermal power plants);

High corrosive systems (condensers, evaporators, sea water desalinations, fertilizing, urea systems, ammonia, gas, corrosive acids);

The petroleum, chemical and petrochemical industries;

The food processing and refrigeration industries;

Natural gas treatment;