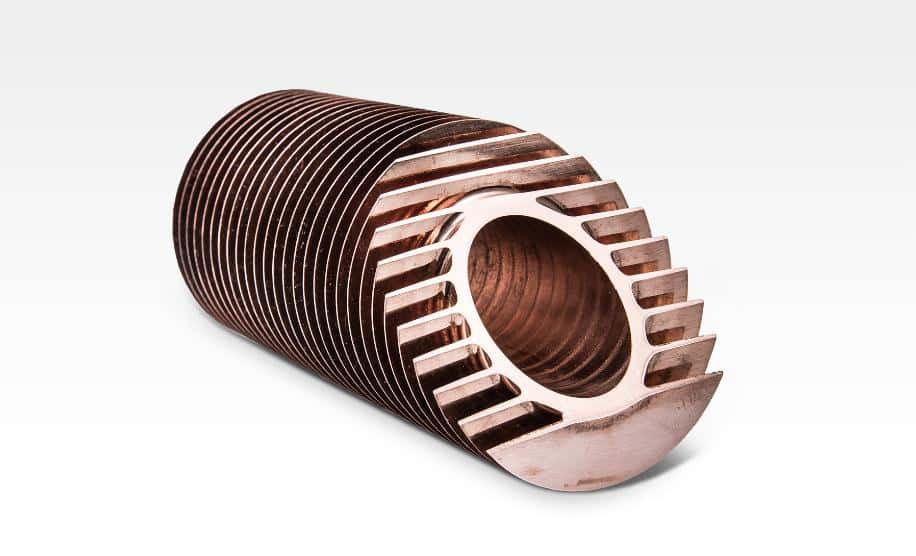

Low finned tubes involve rotational processing of the outer surface of steel tubes to create a fin shape. A steel pipe length of 25.4 mm (1 inch) per fin and 19 fins is a design often used.

We can also produce units with 26 fins. The pipe’s outer surface area becomes 3.5 times that of the inner surface area and possesses superior heat transferability compared to normal, round pipes. By improving the heat transferability of a pipe, it can minimize (capacity, weight reduction) into a variety of devices, reduce material cost, reduce shipping cost, and improve the amount of space taken up.

The uses differ, but as far as pipes with an increased outer surface area are concerned, they are all tubes with welded peripheral fins onto steel pipes, also known as high fin tubes. Low finned tubes involve the formation of fins by direct rotational processing of steel pipes, meaning there is no worry of detachment even if later bent. Moreover, they possess excellent durability and anti-vibration properties once put into operation.

We produce 2 versions of fins per inch. On a steel pipe length of 25.4 mm (1 inch) you can choose 19 fins or 26 fins. 19 fins per inch is the design often used.

Even high finned tubes are available through a partnership with cooperating companies, so please feel free to inquire. With high finned tubes, fins can be made from aluminum or stainless steel. By combining cold drawn steel tubes and high fin processing, we can respond to customer’s material, delivery deadline, and quantity needs as far as possible.

Our plant capability:

- 4 finning production lines and 4 ‘U’ bending lines

- Fins per inch-19, 26, 28

- Materials- Carbon steel, stainless steel, copper nickel and monel alloy 400

- Tube OD- 15.88mm to 25.40mm

- Max Tube Length-30 metres

- Bending-up to 30 metres max developed length

- Test capability-air under water and Hydrotest

- Heat treatment-electric resistance stress relief annealing

Benefits of Low Finned Tubes:

- Offers 2.5-3 times the external surface area of bare tube

- Enhanced heat exchanger efficiency means less tube is required to accomplish the same heat transfer as a bare tube

- Low finned tube can increase the performance of an existing exchanger without the difficult and expensive task of building new shells etc

- Reduced space and weight can be extremely valuable in offshore production or high elevation distillation columns. Low finned technology can transform large shell and tube exchangers into compact heat exchangers

Material description: stainless steel 304 and 316, steel pipe (10#, 20#), duplex steel 2205, titanium pipe

| Specification | wall thickness(mm) | Pitch(mm) | Fin Height(mm) | Defining high wall thickness(mm) |

| Ф16 | 1.2 | 0.8-1.33 | 0.8-1 | 0.8 |

| 2 | 0.8-1.45 | 1.6-1.2 | ||

| Ф19 | 2.1 | 1-1.45 | 1.6-1.2 | |

| 2.77 | 2.3-1.6 | |||

| Ф25 | 2 | 1.5-1.2 | ||

| 2.77 | 2.3-2.1 | |||

| Ф28 | 2.77 | 2.5-2.1 |

List of low finned tube dimensions and heat transfer area

①、Outer Diameter:19mm

| Material | Fin Span(mm) | Fin Height(mm) | External Surface Area | Fin Ratio |

| Stainless Steel | 0.75 | 0.5 | 0.134 | 2.23 |

| 1.0 | 0.8 | 0.147 | 2.45 | |

| 1.3 | 1.30 | 0.164 | 2.73 | |

| Carbon Steel | 1.0 | 1.0 | 0.168 | 2.8 |

| 1.3 | 1.5 | 0.178 | 2.97 | |

| Light Pipe | – | – | 0.06 | – |

②、Outer Diameter:25mm

Material

| Fin Span(mm) | Fin Height(mm) | External Surface Area | Fin Ratio |

| Stainless Steel | 0.75 | 0.5 | 0.18 | 2.25 |

| 1.0 | 0.8 | 0.199 | 2.49 | |

| 1.3 | 1.30 | 0.223 | 2.79 | |

| Carbon Steel | 1.0 | 1.0 | 0.227 | 2.84 |

| 1.3 | 1.5 | 0.243 | 3.04 | |

| Light Pipe | – | – | 0.08 | – |

In order to forward you a promt offer we would be pleased to receive you detailed enquiry including:

• Base tube material

• Base tube size (OD x WT x Length)

• Fin material

• Fin type

• Fin diameter or height

• Fin thickness

• Fins per inch, meter or fin pitch

• Lenght of plain, unfinned ends

• Finned Tube Quantity

(Additional fabrication, such as bend or weld the tubes into tubeplate or assembly)

| Place of Origin: | China.Imported materials are available. |

| Brand Name: | Datang |

| Certification: | ISO… |

| Model Number: | Integral Rolling |

Contact Us:datangfintube@gmail.com