What is a Shell and Tube Heat Exchanger?

A shell and tube heat exchanger (also known as a shell-and-tube heat exchanger) uses the walls of the tube bundle enclosed in the shell as the heat transfer surface. This type of heat exchanger has a simple structure, low cost, a wide flow cross-section, and is easy to clean against scale; however, it has a low heat transfer coefficient and occupies a large footprint. It can be manufactured from a variety of structural materials (primarily metal) and can operate under high temperatures and high pressures, making it the most widely used type.

Shell and tube heat exchangers include fixed tube sheet steam-water heat exchangers, shell and tube steam-water heat exchangers with expansion joints, floating head steam-water heat exchangers, U-shaped shell and tube steam-water heat exchangers, corrugated shell and tube steam-water heat exchangers, and segmented water-water heat exchangers. The main control parameters of shell and tube heat exchangers include heating area, hot water flow rate, heat transfer capacity, and heat medium parameters.

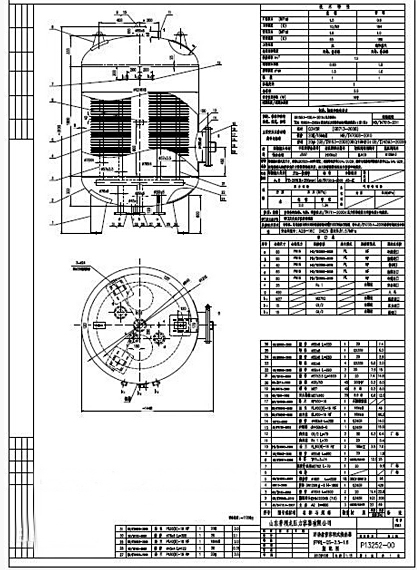

Shell-and-Tube Heat Exchanger Structure

A shell-and-tube heat exchanger consists of a shell, heat transfer tube bundle, tube sheet, baffles (baffles), and tube box. The shell is typically cylindrical, housing the tube bundle, which is fixed to the tube sheet at both ends. The hot and cold fluids involved in the heat exchange flow: one inside the tubes, known as the tube-side fluid; the other outside the tubes, known as the shell-side fluid.

To improve the heat transfer coefficient of the fluid outside the tubes, several baffles are typically installed within the shell. These baffles increase the velocity of the shell-side fluid, forcing the fluid to pass through the tube bundle multiple times along a prescribed path, thereby increasing fluid turbulence. The heat exchange tubes can be arranged on the tube sheet in an equilateral triangle or square configuration. The equilateral triangle arrangement is more compact, resulting in higher turbulence and a higher heat transfer coefficient. The square arrangement facilitates cleaning of the tubes and is suitable for fluids prone to scaling.

The main control parameters of a shell-and-tube heat exchanger include heating area, hot water flow rate, heat transfer capacity, and heat medium parameters.

Each time the fluid passes through the tube bundle is called a tube pass; each time it passes through the shell is called a shell pass. The diagram shows the simplest single-tube-shell heat exchanger, referred to as a Type 1-1 heat exchanger.

To increase the fluid velocity within the tubes, baffles can be installed in the tube boxes at both ends, dividing the tubes into several groups. This allows the fluid to pass through only a portion of the tubes at a time, resulting in multiple round trips through the tube bundle. This is called multiple tube passes.

To increase the flow velocity outside the tubes, longitudinal baffles can also be installed in the shell, forcing the fluid to pass through the shell space multiple times. This is called multiple shell passes. Multiple tube passes and multiple shell passes can be used in conjunction with each other.

Classification of Shell and Tube Heat Exchangers

In shell and tube heat exchangers, the temperatures of the fluid inside and outside the tubes differ, resulting in different temperatures between the shell and the tube bundle. If the temperature difference between the two is large, significant thermal stress will be generated within the heat exchanger, causing the tubes to bend, break, or pull off the tubesheet. Therefore, when the temperature difference between the tube bundle and the shell exceeds 50°C, appropriate compensatory measures must be taken to eliminate or reduce thermal stress.

Shell-and-tube heat exchangers can be divided into the following main types based on the compensation measures used:

① Fixed-tube-sheet heat exchangers: The tubesheets at both ends of the tube bundle are integrally connected to the shell. This simple structure is only suitable for heat exchange operations where the temperature difference between the hot and cold fluids is small and mechanical cleaning of the shell side is not required. When the temperature difference is slightly larger and the shell side pressure is not too high, a flexible compensation ring can be installed on the shell to reduce thermal stress.

② Floating-head heat exchangers: The tubesheet at one end of the tube bundle floats freely, completely eliminating thermal stress. The entire tube bundle can also be withdrawn from the shell, facilitating mechanical cleaning and maintenance. Floating-head heat exchangers are widely used, but their structure is complex and their cost is high.

③ U-tube heat exchangers: Each heat exchange tube is bent into a U shape and fixed at both ends to the upper and lower sections of the same tubesheet. A partition within the tube box divides the tube into an inlet and outlet chamber. This type of heat exchanger completely eliminates thermal stress and has a simpler structure than the floating-head type, but the tube side is difficult to clean.

④ Vortex Film Heat Exchanger: This vortex film heat exchanger utilizes the latest vortex film heat transfer technology, enhancing heat transfer efficiency by altering the fluid’s motion. As the medium passes through the vortex tubes, it vigorously scours the tube surface, improving heat transfer efficiency. The efficiency can reach up to 10,000 W/m²°C.

This structure offers corrosion resistance, high temperature resistance, high pressure resistance, and anti-scaling properties. Other types of heat exchangers use fixed-direction flow, creating circumferential flow around the tube surface, reducing the convective heat transfer coefficient.

Performance comparison of various types of heat exchangers:

| Comparison Item | Floating Tube Heat Exchanger | Threaded Tube Heat Exchanger | Eddy Current Heat Exchanger |

|---|---|---|---|

| Applicable Media | Steam, Water | Steam, Water | Weakly corrosive chemical materials, Steam, Water |

| Media Parameter Range | Temperature: 0-150°C | Temperature: 0-150°C | Temperature: -40-400°C |

| Pressure: 0-1.0MPa | Pressure: 0-1.6MPa | Pressure: 0-10.0MPa | |

| Thermal Efficiency | 92% | 93% | 96% |

| Anti-scaling Performance | Automatic descaling | Manual descaling | Anti-scaling function |

| Vibration & Noise | High vibration, loud noise | Low vibration, quiet noise | Minimal vibration, quiet noise |

| Service Life | ~7 years | ~10 years | ~20 years |

| Maintenance | Shutdown maintenance, tube bundle replacement | Shutdown maintenance, tube pulling and re-expanding | No maintenance required |

Features of Shell-and-Tube Heat Exchangers

1. Highly efficient and energy-efficient, this heat exchanger boasts a heat transfer coefficient of 6000-8000 W/m².0°C.

2. Made entirely of stainless steel, it offers a long service life of over 20 years.

3. Shifts from laminar flow to turbulent flow, improving heat transfer efficiency and reducing thermal resistance.

4. High heat transfer speed, high temperature resistance (400°C) and high pressure resistance (2.5 MPa).

5. Compact structure, small footprint, lightweight, easy installation, and reduced civil engineering investment.

6. Flexible design, comprehensive specifications, and practical, targeted solutions save money.

7. Widely applicable, suitable for a wide range of pressures and temperatures, and for heat exchange with a variety of media.

8. Low maintenance, easy operation, long cleaning cycles, and convenient cleaning.

9. Utilizes nano-thermal film technology, significantly increasing the heat transfer coefficient.

10. Broad application areas, including thermal power, factories and mines, petrochemicals, urban centralized heating, food and pharmaceuticals, energy electronics, and machinery and light industry. 11. The heat transfer tubes utilize copper tubes with rolled fins on the outer surface, offering high thermal conductivity and a large heat transfer area.

12. The guide plates guide the shell-side fluid in a continuous, zigzag flow pattern within the heat exchanger. The guide plate spacing can be adjusted to optimize the flow rate. The robust structure accommodates high and even ultra-high flow rates and high pulsation rates.

13. When the shell-side fluid is oil, it is suitable for heat transfer with low-viscosity and relatively clean oils.

Key Points for Heat Exchanger Selection

1) Determine the required heat exchange area based on the known flow rates of the cold and hot fluids, their initial and final temperatures, and their specific heat capacities. To make a preliminary estimate of the heat exchange area, generally assume the heat transfer coefficient, determine the heat exchanger structure, and then verify the heat transfer coefficient K.

2) When selecting a heat exchanger, consider the pressure rating, operating temperature, and interface connection conditions. If the pressure drop and installation conditions allow, consider shell-and-tube heat exchangers with smaller diameters and extended lengths to maximize heat transfer.

3) The pressure drop across the heat exchanger should not be excessive, generally ranging from 0.01 to 0.05 MPa.

4) The flow rate should take into account the fluid viscosity. For highly viscous fluids, the flow rate should be less than 0.5 to 1.0 m/s. The flow rate within the pipe should generally be 0.4 to 1.0 m/s; for fluids prone to scaling, the flow rate should be 0.8 to 1.2 m/s.

5) Install a filter before high-temperature water enters the heat exchanger.

6) The combined results of the single unit processing and configuration number of heat exchangers in the heat exchange station should meet the total heating load and regulation requirements of the heat exchange station. Under the premise of meeting the user’s heat load regulation requirements, the number of heat exchangers in the same heating coefficient should not be less than 2 and not more than 5.

Key Points for Shell-and-Tube Heat Exchanger Installation

1) The heat exchanger should be subjected to a hydraulic pressure test at 1.5 times the maximum operating pressure. The steam section should be tested at a pressure not less than the steam supply pressure plus 0.3 MPa; the hot water section should be tested at a pressure not less than 0.4 MPa. Maintain the pressure at the test pressure for 10 minutes without a drop.

2) Space should be left at the front of the shell-and-tube heat exchanger for removal of the tube bundle. This means the distance between the end cap and the wall or roof should not be less than the length of the heat exchanger. The clear width of the equipment operating access should not be less than 0.8 m.

3) Valves and instruments should be installed at a height that allows for easy operation and observation.

4) The vertical clearance from the highest point of the heater’s upper attachment (generally the safety valve) to the lowest point of the building structure must meet installation inspection requirements and must not be less than 0.2 m.

Shell-and-Tube Heat Exchanger Corrosion Analysis

Shell-and-tube heat exchangers are typically made of carbon steel, stainless steel, and copper. When used in coolers, carbon steel tubesheets often experience corrosion and leakage in the welds between the tubesheets and tubes. Leakage enters the cooling water system, polluting the environment and causing material waste.

During shell-and-tube heat exchanger manufacturing, manual arc welding is typically used. This weld seam can exhibit varying degrees of defects, such as dents, pores, and slag inclusions, and the stress distribution along the welds is uneven.

During operation, the tubesheets typically come into contact with industrial cooling water. Impurities, salts, gases, and microorganisms in this water can cause corrosion to the tubesheets and welds, a phenomenon commonly referred to as electrochemical corrosion.

Industrial water, whether freshwater or seawater, contains various ions and dissolved oxygen. Fluctuations in the concentrations of chloride ions and oxygen play a significant role in determining the corrosion pattern of the metal. Furthermore, the complexity of the metal structure also influences the corrosion morphology.

Corrosion in the welds between the tubesheets and tubes is primarily characterized by pitting and crevice corrosion. From the outside, there are many corrosion products and deposits on the surface of the tube sheet, and there are pits of varying sizes.

When seawater is used as the medium, galvanic corrosion will also occur. Chemical corrosion is the corrosion of the medium. When the heat exchanger tube sheet contacts various chemical media, it will be corroded by the chemical medium. In addition, a certain amount of bimetallic corrosion will occur between the heat exchanger tube sheet and the heat exchange tube.

Factors affecting shell and tube heat exchangers

In summary, the main factors affecting the corrosion of shell and tube heat exchangers are:

(1) Medium composition and concentration: The influence of concentration varies. For example, in hydrochloric acid, the higher the concentration, the more severe the corrosion. Carbon steel and stainless steel corrode most severely in sulfuric acid with a concentration of about 50%, but when the concentration increases to above 60%, the corrosion rate decreases sharply.

(2) Impurities: Harmful impurities include chloride ions, sulfur ions, cyanide ions, ammonia ions, etc. These impurities can cause severe corrosion in some cases.

(3) Temperature: Corrosion is a chemical reaction. For every 10°C increase in temperature, the corrosion rate increases by about 1 to 3 times, but there are exceptions.

(4) pH value: Generally, the lower the pH value, the greater the corrosion of the metal.

(5) Flow rate: In most cases, the greater the flow rate, the greater the corrosion.