Why use H-type fin tubes in boiler economizers?

H-type fin tubes utilize parallel, welded pairs of fins to break through heat transfer barriers. Their self-cleaning structure significantly enhances flue gas flow, saving power plants a significant cost per kilowatt-hour (kWh) and supporting a significant increase in boiler efficiency.

The main reasons for choosing H-type fin tubes in boiler economizers can be summarized as follows, taking into account their structural characteristics and the actual needs of thermal power plants:

1. Highly Efficient Heat Transfer

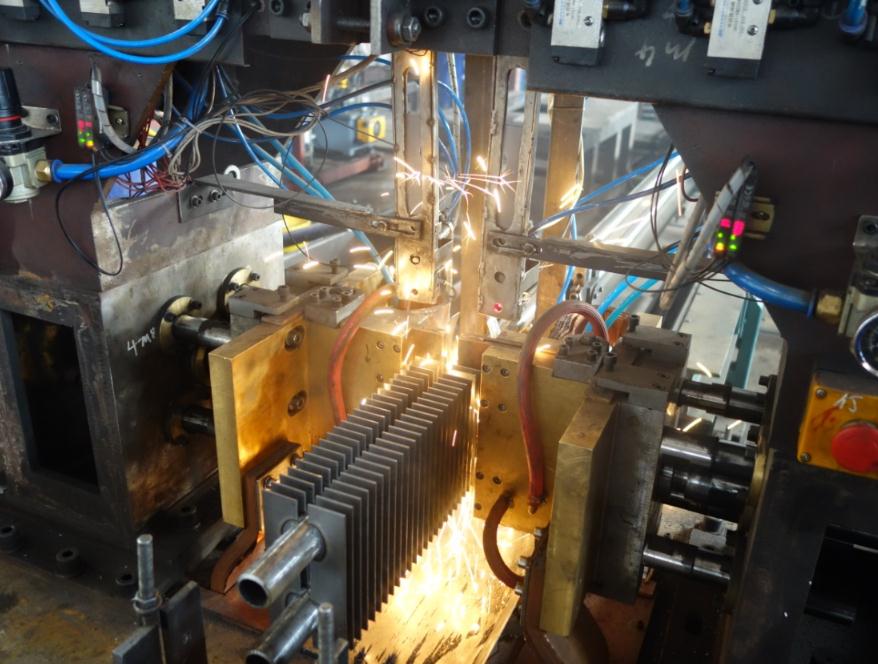

Expanded Surface Area: The unique design of the H-type fin (two fins arranged in parallel, welded together to form an “H” shape) significantly increases the heat transfer area, improving heat transfer efficiency between flue gas and the working medium (water/steam).

Enhanced Heat Transfer through Turbulence: The H-type structure generates more turbulence in the flue gas flow, disrupting the boundary layer, reducing thermal resistance, and thus enhancing heat transfer.

2. Excellent Anti-Dust Accumulation

Anti-Clogging Structural Design: The narrow passages between the H-shaped fins create a “flue corridor,” preventing fly ash particles from settling under the airflow. The welded sections prevent ash from entering the fin gaps, reducing the risk of clogging.

Self-Cleaning: When high-speed flue gas passes through, the vibration and flushing action between the fins automatically removes some accumulated dust, reducing maintenance frequency.

3. Wear Resistance and Long Life

Structural Stability: The H-shaped fins’ welding process enhances overall rigidity, making them more wear-resistant than spiral fins and particularly suitable for flue gas environments with high ash concentrations.

Material Compatibility: High-temperature and corrosion-resistant alloy steels (such as ND steel or Corten steel) are typically used, extending service life under harsh operating conditions.

4. Low Flow Resistance and Energy Saving

Optimized Airflow Distribution: The H-shaped arrangement reduces flue gas flow resistance, lowering power consumption for the induced draft fan while also preventing wear problems caused by excessive localized flow velocities.

5. Economical and Easy Maintenance

Reduced Maintenance Costs: The dust-proof design reduces downtime for cleaning, saving labor and maintenance costs.

Installation Flexibility: The modular design facilitates replacement and repair, and the mature manufacturing process ensures a low overall cost.

Advantages of H-Type Fin Tubes Compared to Other Fin Tube Types

Compared to spiral fin tubes: While spiral fins have a large heat transfer area, they are prone to dust accumulation and have low structural strength. H-Type fins offer superior clogging resistance and durability.

Compared to longitudinal fin tubes: H-Type fins expand their surface area on both sides and offer better resistance to dust accumulation, making them suitable for high-ash flue gases.

Applications of H-Type Fin Tubes

H-Type fin tubes are particularly well-suited for economizers, air preheaters, and waste heat recovery units in thermal power plants, and perform particularly well when burning high-ash coal or biomass fuels.

The key reason for choosing H-Type fin tubes in thermal power plant boiler economizers is their balance of efficient heat transfer, dust resistance, durability, and cost-effectiveness. They can significantly improve boiler efficiency and reduce lifecycle costs, making them an ideal choice for handling demanding flue gas conditions.