Aluminum Finned Tubes

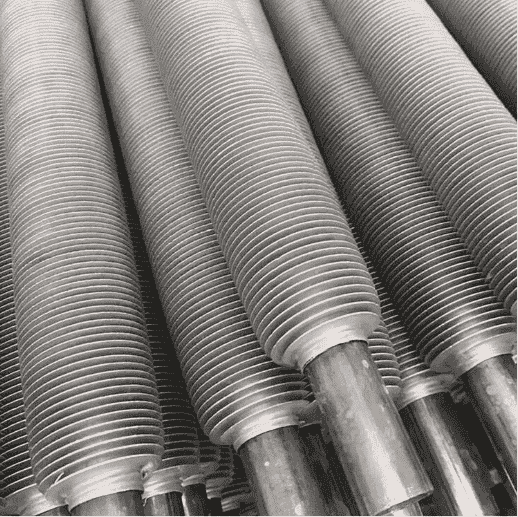

L-Foot Tension Wound Finned Tubes

Aluminum L-Foot Tension Wound Finned Tubes are an economical solution for applications requiring greater resistance to vibration and heat cycling typical of air cooled heat exchangers.

The L-Foot design mechanically locks the fins and provides broader contact surface between tube and fin.

Below you will see common L-Foot Tension Wound Finned Tube configurations:

Tube Sizes: 1/2″ O.D. to 2″ O.D.

Fin Heights: 1/4″ to 5/8″

Fin Pitch: 4 to 13 fins per inch

Temperature: Up to 300°F

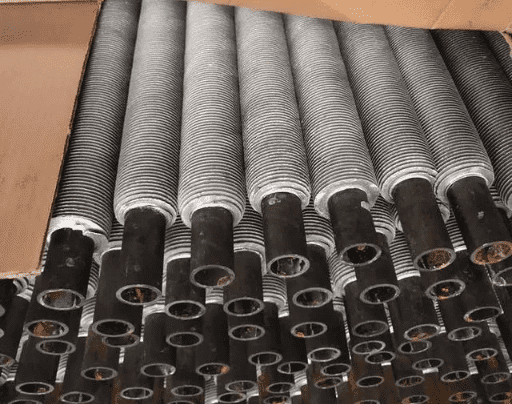

Edge Tension Wound Finned Tubes

Edge Tension Wound Finned Tubes offer a low cost solution for low to moderate temperature applications. The surface of the tube is knurled as the fin is wound tightly on edge around the O.D. of a tube to ensure proper fin to tube contact.

Edge Tension Wound Finned Tubes are commonly used in applications with small amounts of vibration and metal temperatures up to 250° Fahrenheit.

Tube Sizes: 1/2″ O.D. to 2″ O.D.

Fin Heights: 1/4″ to 1″

Fin Pitch: 4 to 13 fins per inch

Embedded Finned Tubes

Embedded Fin Tubes offer solutions where higher temperatures, continuous thermal cycling and tube vibration due to high velocity air streams can cause failures. The fin is mechanically embedded into a groove that is plowed in the tube O.D. and is locked into place by rolls that force the groove to tightly close around the fin base.

Tube Sizes: 9/16″ O.D. to 2″ O.D.

Fin Heights: 1/4″ to 5/8″

Fin Pitch: 5 to 13 fins per inch

Aluminum Finned TubesExtruded Finned Tubes

Extruded Finned Tubes provide the greatest resistance to atmospheric corrosion. The aluminum fin material completely encloses the tube, except at the ends where a tube coating can be applied.

Where atmospheric corrosion is present and when operated within design temperature limits, extruded finned tubes provide the most stable performance over time as compared to the other fin types. The fin is rolled from an outer aluminum tube by a process using pressure to create a rolled “pressure bond” between the liner tube and fins.

Extruded Finned Tubes are commonly used in applications with temperatures up to 550 degrees Fahrenheit.

Tube Sizes: 1″ O.D. to 1 1/4″ O.D.

Fin Heights: 1/2″ to 5/8″

Fin Pitch: 8 to 11 fins per inch

Perforated Finned Tubes

Perforated Finned Tubes maximize heat transfer by increasing the air flow across the finned area of the tube. Uniform perforations are created in the fin as it passes through the machine. These perforations are arranged like spokes of a wheel and can manufactured in Embedded and L-Foot fin configurations. Perforated Fins can manufactured out of aluminum or copper.

Tube Sizes: 9/16″ O.D. to 2″ O.D.

Fin Heights: 1/4″ to 1″

Fin Pitch: 4 to 13 fins per inch

| PRODUCT | TYPE | TUBE MATERIAL | FIN MATERIAL | TUBE SIZE | FIN SIZE |

| Heat Exchanger Finned Tube | Extruded Fin Tube | All Kind of Material can be applied | Aluminum A1100 | 15.88~50.8 | 7~11.5FPI |

| Fin Height Max 16mmH | |||||

| L-Foot Fin Tube | All Kind of Material can be applied | Copper C1100, C1220 | 12.70~50.8 | 7~11.5FPI | |

| (Wrap On Type) | Fin Height Max 16mmH | ||||

| G-Fin Tube (Embedded Type) | Aluminum A1100, A1050, A1060 | ||||

| High Frequency Welded Finned Tube | A179 Carbon Steel Tube | Carbon Steel Tube | 12.70~160 | 1.5~7FPI | |

| Stainless Steel Tube | Stainless Steel Tube | 0.8~3.2mm. Thickness | |||

| Alloy Steel Material | Alloy Steel Material | ||||

| Integral Copper & Copper Alloy High Finned Tube | C12200, C11000, C70600 | C12200, C11000, C70600 | 15.88~22.23 | 5~9FPI | |

| Max 12mm. H | |||||

| Oval Finned Tube | Carbon Steel Tube | Carbon Steel Tube | All Size Available | 5~15FPI | |

| Stainless Steel Tube | Stainless Steel Tube | ||||

| Alloy Steel Material | Alloy Steel Material | ||||

| Copper & Copper Alloy Tube | Copper & Copper Alloy Tube | ||||

| Monometallic Fin Tube | Low Fin Tube | Carbon Steel, stainless steel, titanium, copper, brass, nickel alloy, etc. | — | 9.52~40 | 12, 16, 19 28 FPI, etc. |

| Turbo-C Tube | |||||

| Turbo-E Tube | |||||

| Corrugated Tube | All Kind of Material | — | 6.35~40 | 2~9FPI |