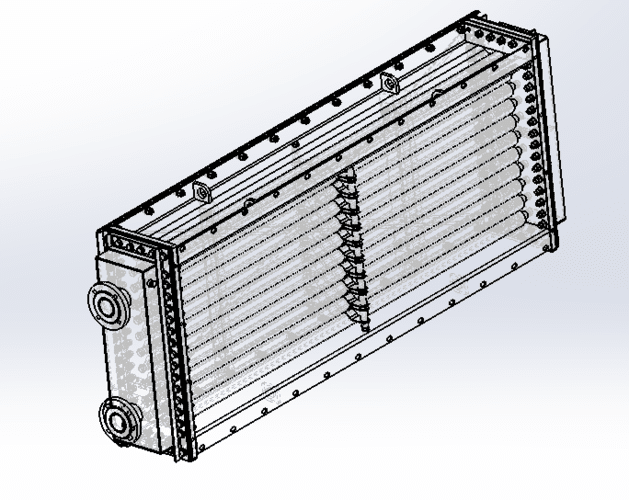

Product advantages: The whole rolled fin tube has no contact thermal resistance, good heat transfer performance, high strength, large heat exchange area per unit length, and long life; the fin surface is smooth and burr-free, no wrinkle, not easy to scale, easy to clean (available High pressure water washing) and remove surface water, low flow resistance, can maintain good heat transfer performance for a long time.

Principle of finned tube heat exchanger – characteristics of finned tube heat exchanger

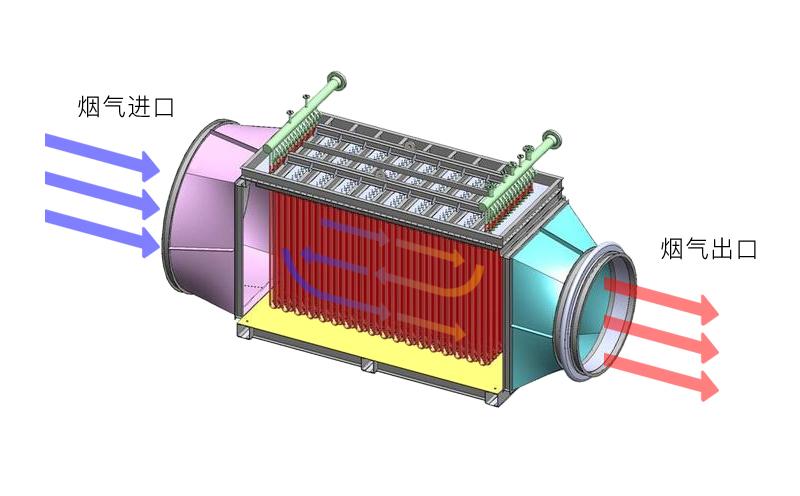

1. High heat transfer efficiency Because the disturbance of the fins to the fluid causes the boundary layer to continuously rupture, it has a large heat transfer coefficient; at the same time, because the partitions and fins are very thin and have high thermal conductivity, the heat transfer of the finned tubes device can achieve high efficiency.

2. Compact Due to the extended secondary surface of the finned tube heat exchanger, its specific surface area can reach 1000㎡/m3.

3. Lightweight The reason is that it is compact and mostly made of aluminum alloy. Now steel, copper, composite materials, etc. have also been mass-produced.

4. Strong adaptability The finned tube heat exchanger can be applied to: gas-gas, gas-liquid, liquid-liquid, heat exchange between various fluids and phase-change heat with collective state change.

Through the arrangement and combination of flow channels, it can adapt to different heat exchange conditions such as counter flow, cross flow, multi-stream flow, and multi-pass flow.

The heat exchange needs of large-scale equipment can be met through the combination of series, parallel, and series-parallel connections between units. In the industry, it can be finalized and mass-produced to reduce costs, and the interchangeability can be expanded through building block combinations.

5. The manufacturing process requires strict and complicated process.

It is easy to block, not resistant to corrosion, and difficult to clean and repair, so it can only be used in occasions where the heat exchange medium is clean, non-corrosive, difficult to scale, difficult to deposit, and difficult to block.