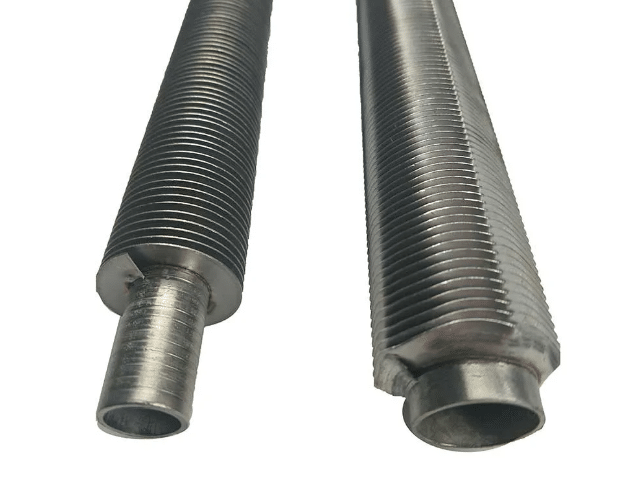

Finned tubes, also known as finned pipes or fin tubes, have become increasingly popular in various industrial applications due to their ability to enhance heat transfer efficiency.

In this article, we will compare finned tubes with traditional tubes to highlight their differences and advantages.

Surface Area:

One of the main advantages of finned tubes over traditional tubes is their larger surface area.

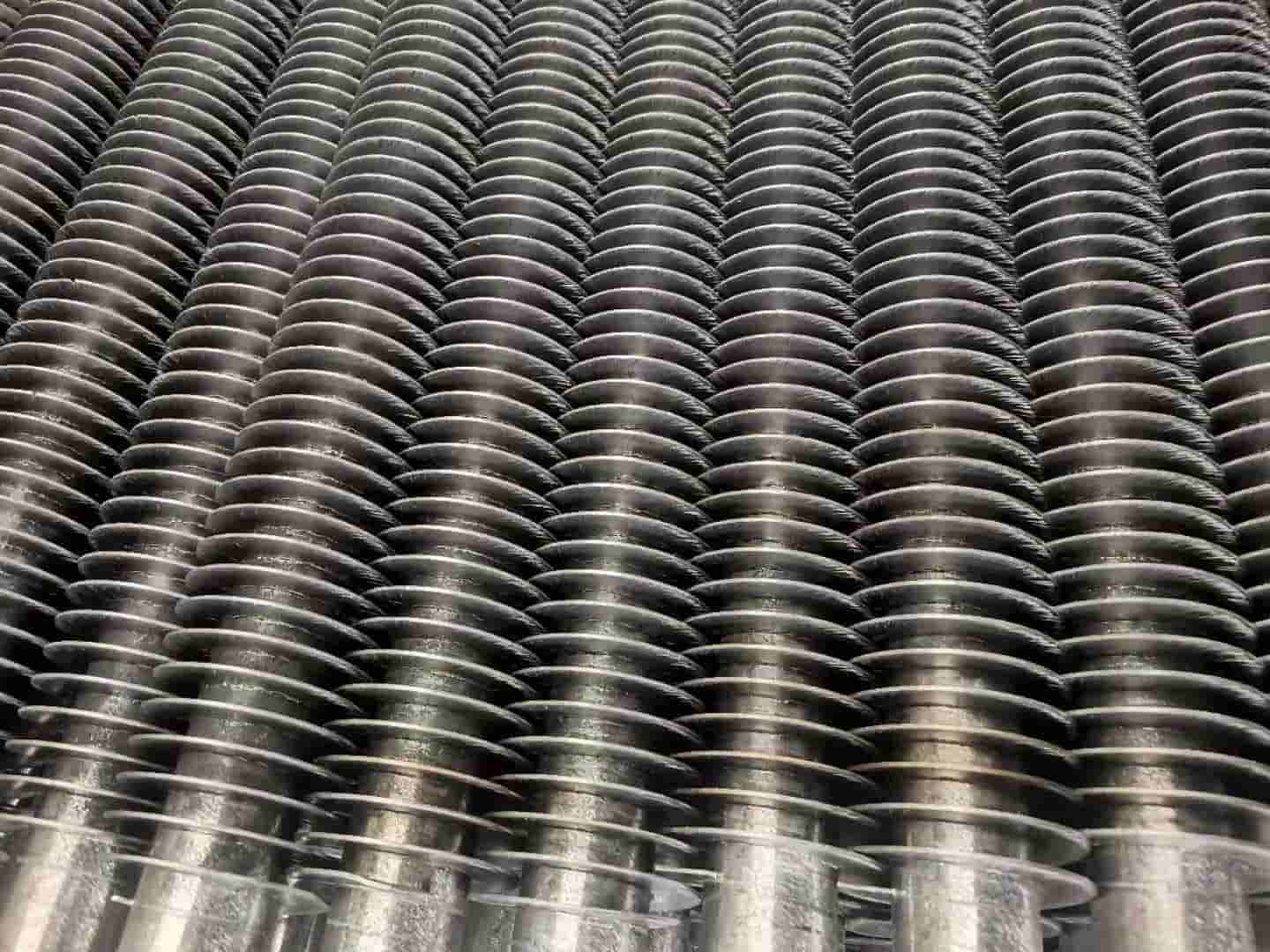

The fins on the outer surface of the tube increase the surface area available for heat transfer, which leads to more efficient heat exchange.

Heat Transfer Efficiency:

Due to the larger surface area, finned tubes have a higher heat transfer efficiency compared to traditional tubes.

This means that finned tubes can transfer more heat between the fluid and the surrounding environment in a shorter time.

Material Selection:

Finned tubes are available in a variety of materials such as copper, aluminum, and stainless steel.

This allows for better customization based on the specific application requirements.

Traditional tubes, on the other hand, are typically limited to materials such as copper or steel.

Cost:

Finned tubes are generally more expensive than traditional tubes due to the additional manufacturing process required to add fins to the tube.

However, the improved heat transfer efficiency can lead to significant cost savings in the long run by reducing energy consumption and increasing equipment lifespan.

Maintenance:

Finned tubes require more frequent maintenance compared to traditional tubes due to the additional fins that can accumulate dirt and debris.

However, regular cleaning can help ensure optimal performance and prevent potential damage to the equipment.

Conclusion:

Finned tubes offer several advantages over traditional tubes such as higher heat transfer efficiency, larger surface area, and better material selection.

While they may be more expensive and require more frequent maintenance, the benefits they provide make them a popular choice in various industrial applications.

Understanding the differences between finned tubes and traditional tubes is crucial for selecting the appropriate type based on the specific application requirements.