Ice making equipment is commonly used in various industries such as food processing, pharmaceuticals, and chemical manufacturing.

It is used to produce ice in large quantities for different purposes like cooling, freezing, and preservation. To produce ice efficiently, heat transfer is essential, and this is where finned tubes come in.

In this article, we will discuss the application of finned tubes in ice making equipment.

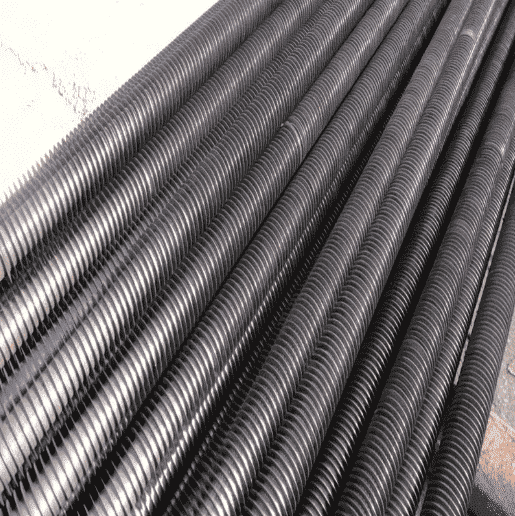

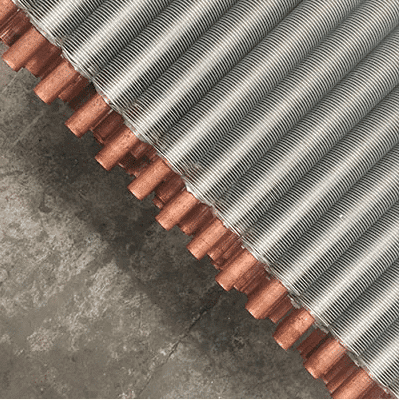

Finned tubes are tubes with extended surfaces that increase their heat transfer area. They consist of a base tube and a series of fins attached to the tube’s outer surface.

The fins increase the tube’s surface area, which in turn enhances the heat transfer process. Finned tubes are commonly used in heat exchangers, and they play a significant role in improving the heat transfer efficiency of the system.

In ice making equipment, finned tubes are used in the evaporator section, which is responsible for the ice-making process.

The evaporator is a heat exchanger that allows the refrigerant to absorb heat from the water and form ice. The water flows through the tube, and the refrigerant flows around the tube in the opposite direction.

As the refrigerant absorbs heat, it changes from a liquid to a gas, and this process continues until all the water in the tube has frozen.

The use of finned tubes in the evaporator section of the ice making equipment enhances the heat transfer process.

The fins increase the surface area of the tube, which allows for better contact between the water and the refrigerant. This, in turn, increases the efficiency of the ice-making process, reducing the time it takes to produce ice.

In addition to improving the heat transfer efficiency, finned tubes also reduce the overall size of the ice making equipment.

Because the fins increase the heat transfer surface area, less space is required to achieve the same level of heat transfer.

This results in smaller and more compact ice making equipment, which is ideal for industries with limited space.

Another advantage of using finned tubes in ice making equipment is their durability. Finned tubes are made of materials such as copper, aluminum, and stainless steel, which are resistant to corrosion and wear.

This makes them ideal for use in harsh environments such as the food processing and chemical manufacturing industries, where the equipment is exposed to corrosive agents.

In conclusion, the application of finned tubes in ice making equipment is essential for efficient and effective ice production.

Finned tubes enhance the heat transfer process, reduce the overall size of the equipment, and increase the equipment’s durability.

With the use of finned tubes, industries can produce ice in large quantities, providing cooling, freezing, and preservation capabilities for their products.