Finned tubes are commonly used in various industries to increase the heat transfer efficiency between fluids.

However, they also have a significant application in ocean engineering, particularly in the design of heat exchangers used in offshore oil and gas production.

In this article, we will discuss the application of finned tubes in ocean engineering and their benefits.

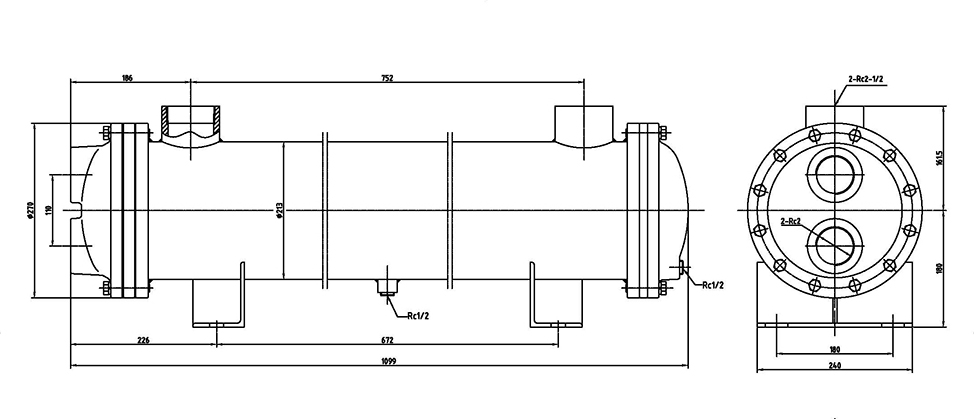

Offshore oil and gas production platforms require heat exchangers to regulate the temperature of various fluids, including seawater, hydrocarbons, and natural gas.

The harsh offshore environment, which includes saltwater corrosion, high humidity, and extreme weather conditions, poses significant challenges to the design and operation of heat exchangers.

Finned tubes provide an effective solution to these challenges.

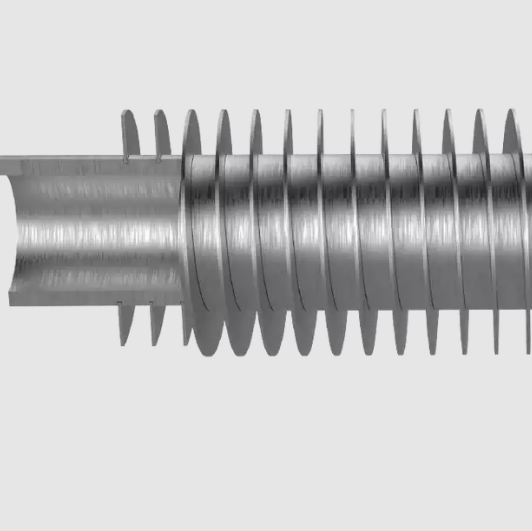

Finned tubes in heat exchangers increase the surface area for heat transfer, allowing for efficient heat transfer even in the presence of corrosive seawater.

The fins provide an additional layer of protection to the tubes, reducing the risk of corrosion and erosion caused by the harsh offshore environment.

This improves the lifespan of the heat exchanger, reduces maintenance costs, and ensures the continuous operation of the offshore platform.

In addition, finned tubes can be designed to withstand extreme temperatures and pressures, making them suitable for use in heat exchangers used in deep-sea oil and gas production.

They can also be customized to meet the specific requirements of the offshore application, such as the size and shape of the fins, the materials used, and the configuration of the heat exchanger.

Finned tubes are also an effective solution for heat transfer in ocean thermal energy conversion (OTEC) systems.

OTEC is a process that utilizes the temperature difference between warm surface water and cold deep ocean water to produce electricity.

The heat exchanger in an OTEC system plays a crucial role in transferring heat from the warm seawater to the working fluid, which drives the power generation cycle.

Finned tubes in the heat exchanger improve the heat transfer efficiency, making the OTEC system more efficient and cost-effective.

In conclusion, the application of finned tubes in ocean engineering, particularly in the design of heat exchangers, provides an effective solution to the challenges posed by the harsh offshore environment.

The increased surface area for heat transfer and the additional layer of protection provided by the fins improve the efficiency and lifespan of the heat exchanger, reducing maintenance costs and ensuring continuous operation of the offshore platform.

Finned tubes are also an effective solution for heat transfer in OTEC systems, improving the efficiency and cost-effectiveness of the power generation process.