In the realm of thermal management, the evolution of finned tube technology has brought forth a series of groundbreaking innovations that have revolutionized heat exchange processes.

From industrial applications to everyday HVAC systems, these innovations have significantly enhanced efficiency, reduced energy consumption, and contributed to more sustainable practices.

In this article, we will explore some of the most noteworthy innovations in finned tube technology that have led to enhanced heat exchange.

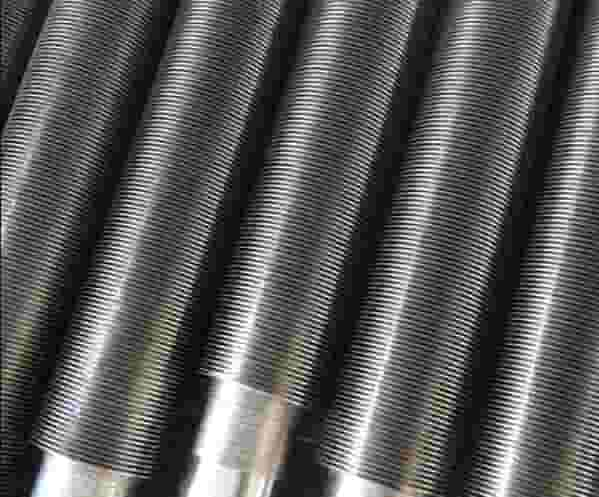

1. Microfin Tubes

Microfin tubes represent a leap forward in heat exchange efficiency.

By incorporating much smaller and closely spaced fins, these tubes dramatically increase the surface area available for heat transfer.

This innovation has resulted in higher heat exchange rates, improved system performance, and reduced size requirements for heat exchangers.

2. Low-Fin Tubes

Low-fin tubes combine the benefits of increased surface area with a reduced fin height.

This design approach minimizes the pressure drop across the system while maintaining optimal heat transfer performance.

Low-fin tubes find applications in various industries, including petrochemical, power generation, and air conditioning.

3. Elliptical Fins

Traditional circular fins have given way to elliptical fin designs.

Elliptical fins optimize the flow dynamics of both air and fluids, improving heat transfer effectiveness.

This innovation is particularly advantageous in applications with limited space or when dealing with irregular flow patterns.

4. Wavy Fin Profiles

Wavy fin profiles disrupt the laminar flow of fluids, promoting turbulence and enhancing heat transfer coefficients.

This innovation is particularly beneficial in applications involving viscous fluids or when dealing with low flow rates.

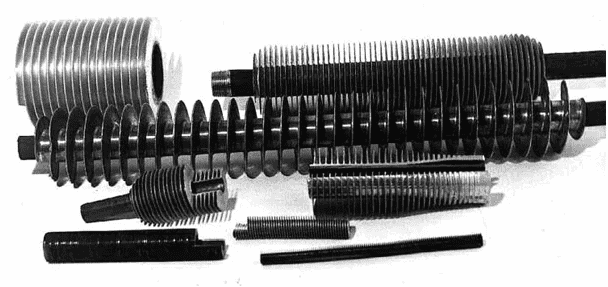

5. Integral Finned Tubes

Integral finned tubes eliminate the risk of fin-tube separation by integrating fins directly into the tube during manufacturing.

This seamless design ensures better heat transfer efficiency, reduced fouling, and improved structural integrity.

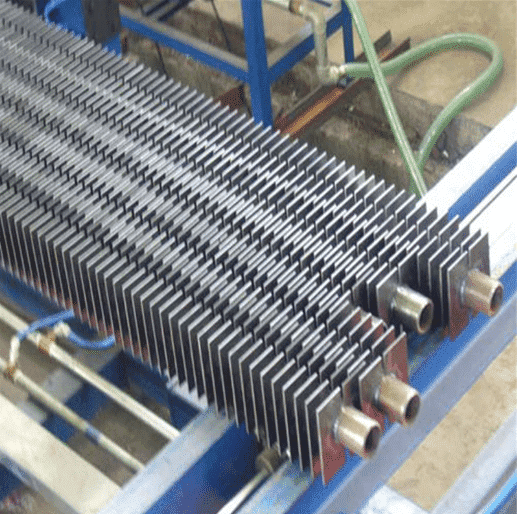

6. Corrugated Fins

Corrugated fins provide higher turbulence levels within the fin-tube assembly, resulting in improved heat transfer rates.

This design innovation is highly effective in applications where fouling is a concern, as it minimizes the accumulation of deposits.

7. Coated Fins

Advancements in coating technology have led to the development of fin coatings that resist fouling, corrosion, and erosion.

These coatings prolong the life of finned tube systems, maintain heat transfer efficiency, and reduce maintenance requirements.

8. Variable Fin Pitch

Variable fin pitch designs adjust the spacing between fins along the length of the tube.

This innovation optimizes heat transfer efficiency by accommodating variations in fluid flow and temperature profiles.

9. Enhanced Materials

Innovative materials, such as aluminum alloys and advanced polymers, have contributed to the lightweighting and improved corrosion resistance of finned tubes.

These materials extend the lifespan of heat exchangers and reduce overall system maintenance.

10. Additive Manufacturing

Additive manufacturing, or 3D printing, has transformed the production of complex fin designs.

This technology enables the creation of intricate and customized fin structures that maximize heat exchange efficiency.

Conclusion

Finned tube technology continues to evolve at a rapid pace, driven by the relentless pursuit of enhanced heat exchange efficiency.

These innovations have far-reaching implications, from increased energy savings to reduced environmental impact.

As industries strive for greater sustainability and operational excellence, the ongoing advancements in finned tube technology promise to play a pivotal role in meeting these objectives.

With each new innovation, the potential to achieve unprecedented levels of heat transfer efficiency becomes not only a reality but also a stepping stone toward a more efficient and sustainable future.