Heat Exchanger Products

Copper Finned Tube and Fin Automotivo Heavy Duty Ac Condenser

Copper finned tube is the core element for enhancing heat transfer in Fin Automotivo Heavy Duty Ac Condenser. By adding fin structure on the outer surface of copper-based tube, its heat exchange area can be expanded by 3 to 10 times compared with plain tube, significantly improving heat transfer efficiency, especially suitable for heat dissipation needs in compact space of construction machinery.

Contact Us:datangfintube@gmail.com

Finned Tube Heat Exchanger Manufacturer

Finned tube heat exchanger achieves efficient energy transfer by expanding the heat transfer area. Its core finned tube can increase the heat exchange capacity by 2-5 times. It has both high efficiency, adaptability and cost advantages. It is a key equipment in the fields of HVAC, electricity, chemical industry, etc. Reasonable maintenance can extend the service life to 10-15 years.

Contact Us:datangfintube@gmail.com

Air Fin Cooler | Air Cooled Heat Exchanger

Air fin cooler is referred to as air cooler or air cooled heat exchanger . It uses air as coolant and can be used as a cooler or a condenser. Air cooler is mainly composed of tube bundle, bracket and fan.

Contact Us:datangfintube@gmail.com

Energy Saving Air Cooled Heat Exchanger With Fans

Air Cooled Heat Exchanger with Fan is a device that uses a fan to force air flow to improve heat exchange efficiency. It is mainly composed of tube bundles, brackets and fans, and adopts the principle of inter-wall heat exchange.

Contact Us:datangfintube@gmail.com

OEM Fin Tube Condenser Manufacturer and Supplier, Factory

Finned tube condenser is a high-efficiency heat exchange device that enhances heat transfer by increasing the surface area of the fins. It is widely used in refrigeration, air conditioning and industrial fields.

Contact Us:datangfintube@gmail.com

Boiler Economizer

Highest quality product

Price saving

Contact Us:datangfintube@gmail.com

Flue Gas Waste Heat Recovery Heat Exchanger

Highest quality product

Price saving

Contact Us:datangfintube@gmail.com

Stainless steel fin tube for refrigeration&evaporator

Highest quality product

Price saving

Contact Us:datangfintube@gmail.com

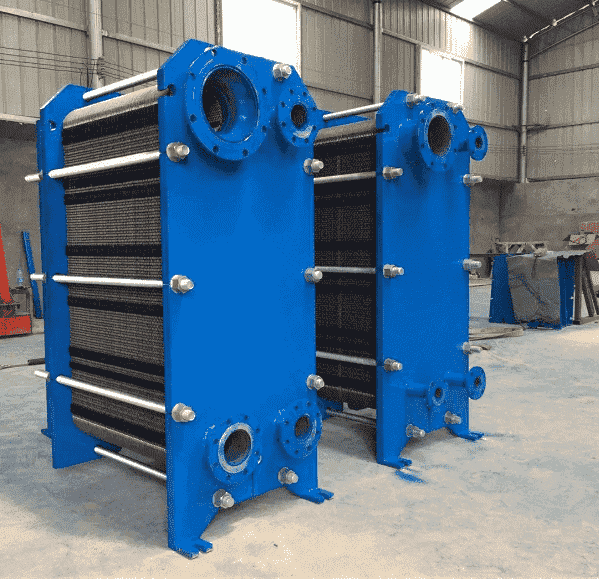

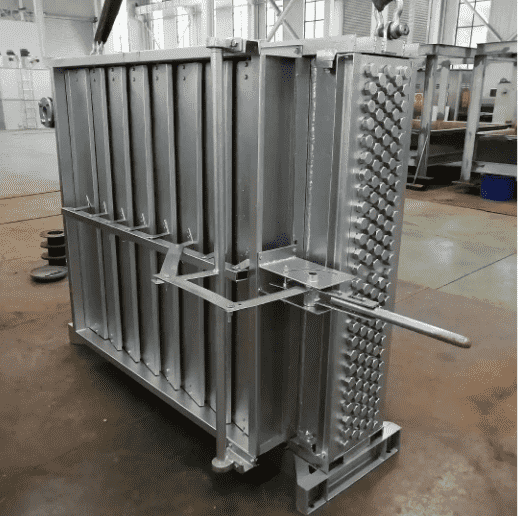

Plate Heat Exchanger Hydraulic Oil Cooler

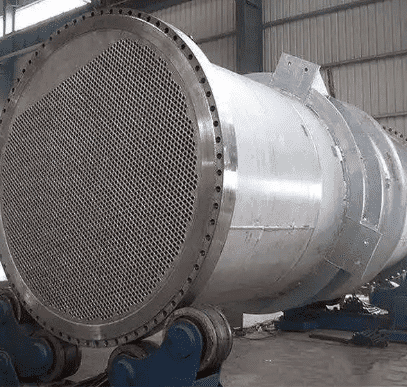

Maximum shell diameter :4600mm

Tube specification:φ19-φ325mm

Tube length:1000-16000mm

Contact Us:datangfintube@gmail.com

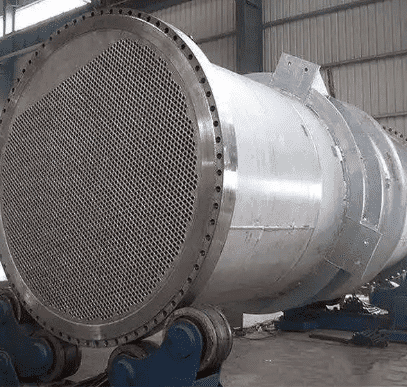

Stainless Steel Shell and Tube Heat Exchanger

The shell and tube exchanger is a kind of heat exchanger that widely applied for chemical and alcohol production.

Contact Us:datangfintube@gmail.com

Stainless Steel Finned Tube Radiators

1.Multiple fin structures can be designed.

2.Automatic welding technology of argon arc deep hole.

3.Flatting and strength expansion technology.

Contact Us:datangfintube@gmail.com

Tube Bundle Heat Exchanger Condenser

ASTM A516 GR70

ASTM A572 GR50

ASTM A537 CL1

Contact Us:datangfintube@gmail.com

Tube Bundle Steam Heat Exchanger

Complete heat exchanger production time is 3-6 weeks.

Replacement Tube Bundles are 2-3 weeks.

Contact Us:datangfintube@gmail.com

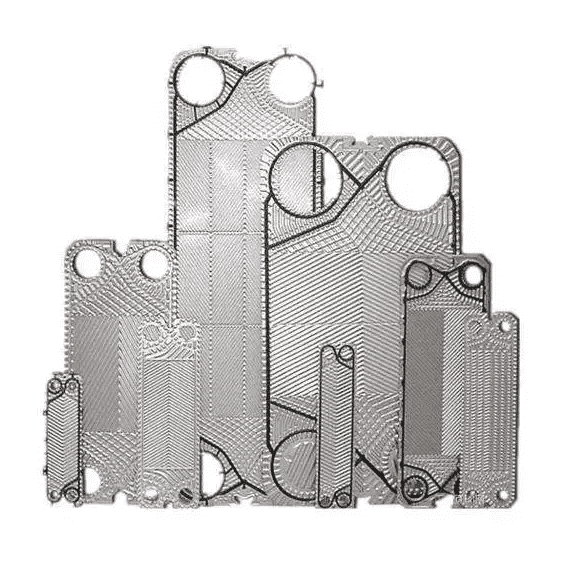

Copper Brazed Heat Exchanger Plate

Length: 7.5”, width: 2.9”, height: 1.2”, heat exchange area: 1.29Ft², with m5-0.8 mounting studs

Refrigeration capacity: 3400 – 17000 BTU/hour, design pressure: 145 psi, test pressure: 290 psi

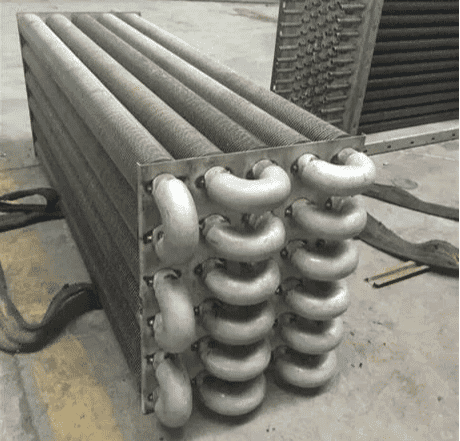

Finned Tube Air Heat Exchangers

HEAT DUTY: 8,712,577.19 KCAL/HR

DESIGN PRESSURE: 20 BARG

DESIGN TEMPERATURE: 250°C

PRESSURE DROP ALLOWED: 122 mm H2O

PRESSURE TEST: 30 BARG

Contact Us:datangfintube@gmail.com

Plate Fin Heat Exchanger

Our aluminum plate fin heat exchangers (PFHEs) are key components in many process plants. Their compact footprint helps save space and costs in a wide range of facilities, including air separation plants, petrochemical and gas treatment plants as well as natural gas and helium liquefaction plants.

Plate Heat Exchanger Design

Easy disassembly for inspection or maintenance

Able to withstand temperature approaches of less than 1°C

“U” or “K “ values three to six times higher than shell and tube exchangers

Finned Tube Air Heat Exchangers

HEAT DUTY: 8,712,577.19 KCAL/HR

DESIGN PRESSURE: 20 BARG

DESIGN TEMPERATURE: 250°C

PRESSURE DROP ALLOWED: 122 mm H2O

PRESSURE TEST: 30 BARG

Contact Us:datangfintube@gmail.com